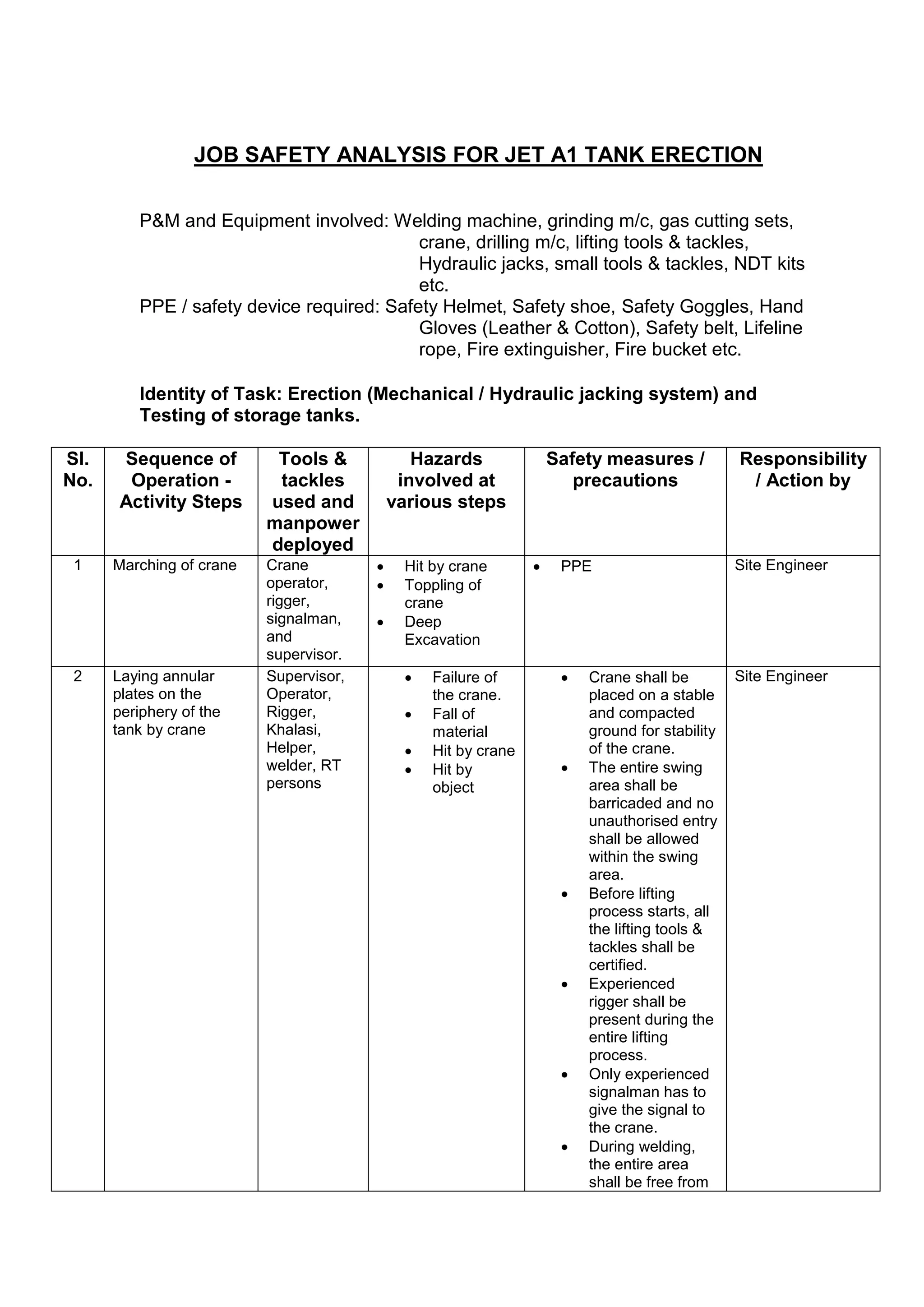

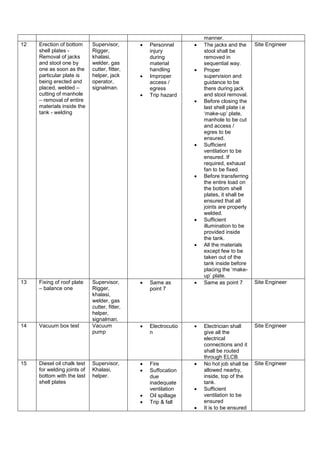

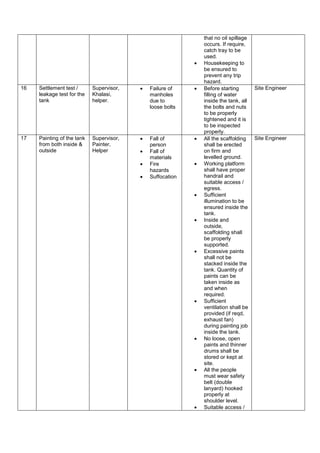

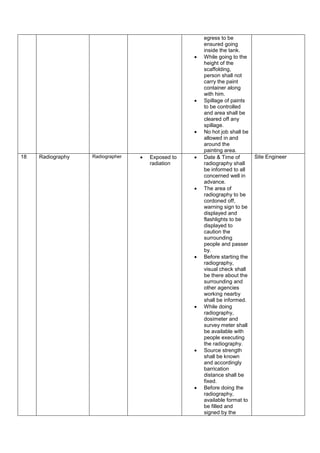

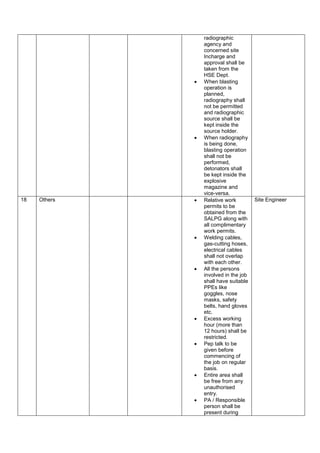

This document provides a job safety analysis for erecting jet fuel storage tanks. It outlines 13 key steps in the erection process and identifies potential hazards at each step, such as falls, being struck by objects, fires, and more. Safety precautions are also listed to mitigate the hazards, including using proper personal protective equipment, restricting access under suspended loads, following proper lifting and staging procedures, and more. The responsibilities of supervisors, riggers, welders and other roles are defined to ensure safety is prioritized throughout the tank erection work.