23 Casting of concrete slabs Risk Assessment Templates.docx

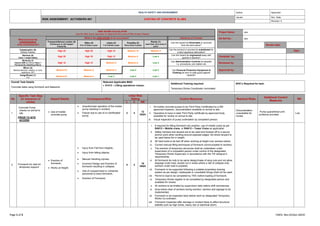

Project Name: xxx RA Ref No.: xxx Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Concrete slabs using formwork and falsework Relevant Applicable MAS: • 01412 – Lifting operations cranes; Additional Training required: Temporary Works Coordinator nominated NOC’s Required for task: RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1 No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Concrete Pump checks on arrival to site PRIOR TO SITE ACCESS • Use of mobile concrete pump • Unauthorized operation of the mobile pump resulting in incident; • Failure due to use of un-certificated pump; 3 4 12 HIGH i. All mobile concrete pumps to be Third Party Certificated by a DM approved inspector, documentation available on arrival to site; ii. Operators to have in-date Third Party certificate by approved body, available for review on arrival to site; iii. Visual inspection of pump undertaken by competent person; Documentation unavailable for review Pump quarantined until evidence provided Low 2. Formwork for slab for temporary support • Erection of formwork; • Works at Height; • Injury from Fall from Heights; • Injury from falling objects; • Manual Handling injuries; • Incorrect Design and Erection of formwork resulting in collapse; • Use of unsupervised or untrained personnel to erect formwork; • Erection of Formwork; 4 4 16 HIGH i. If required for lifting formwork into position, use of mobile crane as per RA012 – Mobile crane, or RA013 – Tower Crane as applicable; ii. Safety harness and lanyard are to be used and hooked off to a secure anchor point when working around exposed edges; No shock lanyard to be used below 6m in height; iii. All hand tools to b

Recommended

Recommended

More Related Content

Similar to 23 Casting of concrete slabs Risk Assessment Templates.docx

Similar to 23 Casting of concrete slabs Risk Assessment Templates.docx (20)

More from Dwarika Bhushan Sharma

More from Dwarika Bhushan Sharma (20)

Recently uploaded

Recently uploaded (20)

23 Casting of concrete slabs Risk Assessment Templates.docx

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 CASTING OF CONCRETE SLABS Issued: Rev. Date: Revision: 0 Page 1 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Concrete Pump checks on arrival to site PRIOR TO SITE ACCESS Use of mobile concrete pump Unauthorized operation of the mobile pump resulting in incident; Failure due to use of un-certificated pump; 3 4 12 HIGH i. All mobile concrete pumps to be Third Party Certificated by a DM approved inspector, documentation available on arrival to site; ii. Operators to have in-date Third Party certificate by approved body, available for review on arrival to site; iii. Visual inspection of pump undertaken by competent person; Documentation unavailable for review Pump quarantined until evidence provided Low 2. Formwork for slab for temporary support Erection of formwork; Works at Height; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Incorrect Design and Erection of formwork resulting in collapse; Use of unsupervised or untrained personnel to erect formwork; Erection of Formwork; 4 4 16 HIGH i. If required for lifting formwork into position, use of mobile crane as per RA012 – Mobile crane, or RA013 – Tower Crane as applicable; ii. Safety harness and lanyard are to be used and hooked off to a secure anchor point when working around exposed edges; No shock lanyard to be used below 6m in height; iii. All hand tools to be tied off when working at height over workers below; iv. Correct manual lifting techniques of formwork communicated to workers; v. The erection of temporary structures shall be undertaken under supervision of a competent person under control of the designated Temporary Works Supervisor in accordance with the TW designer’s requirements; vi. All formwork tie rods to be same design/make of wing nuts and not allow slippage under load, double nut in areas where a risk of collapse onto workers under load is possible; vii. Formwork to be supported following a suitable proprietary bracing system as per design, inadequate or unsuitable fixings shall not be used; viii. Permit to load to be completed by TWC before loading of formwork; ix. Temporary Works register to be completed by designated person and available for review; x. All workers to be briefed by supervision daily before shift commences; xi. Area below clear of workers during erection, barriers and signage to be implemented; xii. Formwork to be inspected daily before work by designated Temporary Works Co-ordinator; xiii. Formwork inspected after damage or incident likely to affect structural stability such as high winds, heavy rain or electrical storm; Project Name: xxx RA Ref No.: xxx Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Concrete slabs using formwork and falsework Relevant Applicable MAS: 01412 – Lifting operations cranes; Additional Training required: Temporary Works Coordinator nominated NOC’s Required for task: RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 CASTING OF CONCRETE SLABS Issued: Rev. Date: Revision: 0 Page 2 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR xiv. No overloading of formwork, TWC shall follow design SWL when distributing materials; 3 Falsework to provide temporary support to formwork Works at Height; Manual Handling; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Incorrect Design and Erection of falsework resulting in collapse; Use of unsupervised or untrained personnel to erect falsework; Erection of Falsework; 4 4 16 HIGH i. Safety harness and lanyard are to be used and hooked off to a secure anchor point; ii. No shock lanyard to be used below 6m in height; iii. All hand tools to be tied off when working at height; iv. Falsework to be protected when adjacent to traffic routes with suitable barriers, and indicated by signage; v. Correct manual lifting techniques of falsework communicated to workers; vi. The erection of temporary structures shall be undertaken by a competent persons under control of the designated Temporary Works Supervisor in accordance with the TW designer’s requirements; vii. All workers to be briefed and TBT by supervision daily before shift commences; viii. Falsework shall be sited on graded, compacted, level ground erected to standards, with consideration given to soil erosion from heavy rain etc.; ix. Area below to be clear of workers during erection, barriers and signage to be implemented; x. Falsework to be inspected daily before work by designated Temporary Works Co-ordinator; xi. Written report weekly on falsework by Engineers, document filed; xii. Falsework inspected after damage or incident likely to affect structural stability such as high winds, heavy rain or electrical storm; xiii. No alterations to falsework by untrained persons; xiv. No overloading of falsework, TWC shall follow design SWL when distributing materials; xv. Ensure good standard of lighting, at night, for the work area. Extreme weather conditions (E.g.: Heavy wind, Sand storm etc.) Regular TBT’s & Trainings to be given on working at heights. Low 4 Rebar to slabs Use of crane; Lifting operations; Persons underneath load struck by falling materials; Rebar bundles swinging / spinning uncontrolled; Damage to slings from sharp edges; Over-sailing of material over workers; Burns/cuts from grinding equipment; Injury from slips/trips on rebar; 3 3 9 MED i. Risk Assessment 12 – mobile Crane to be adhered to regarding lifting of rebar bundles; ii. Workers to wear gloves when tying rebar; iii. Rebar to be stored correctly on deck to ensure safe access and high level of housekeeping maintained; iv. All electrical cutting equipment to be tested and safe to use. Operators shall wear safety glasses; v. Hot work permit required when cutting rebar at height; vi. Access planks to be laid on rebar to provide safe walking access to workers, to be maintained as task progresses; vii. Daily clean-up of waste material to a designated area or skip below; Safe access to be provided, such as scaffold stairs, to work area; 5 Access of mobile pump and delivery trucks to work areas Plant and workers in same working area; Collision with plant or vehicles and live traffic; Workers struck by plant, very high risk of fatality; Uncontrolled pump and truck reversing; 3 4 12 HIGH i. Worker pedestrian routes to be designed and implemented with clear signage to provide segregation; ii. Instruction to workers at induction on use of access routes around the project; iii. Flagmen to be used to control Pump and delivery truck movements; iv. The Logistics plan shall clearly illustrate pump access and egress points; Workers not complying with flagmen Regular topic in TBT’s Low 6 Siting and setting up of concrete pump Working in proximity to existing structures and services; Overturning due to incorrect siting or incorrect pump outrigger extension; Collision of jib with overhead services; Blocking access routes with pump; 3 4 12 High i. If required for concrete pump as per RA014 – Use of Concrete Pump; ii. Ensure pump is set up/rigged out correctly, is on firm level ground as per siting plan with outriggers fully extended; iii.Solid barriers should be situated, where practicable, to protect pump from traffic routes around working radius of cab; Unable to fully extend outriggers due to restrictions in area Operation revised, pump moved to new area; Pump never used without full outrigger extension Low

- 3. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 CASTING OF CONCRETE SLABS Issued: Rev. Date: Revision: 0 Page 3 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR Jib striking stationary structures; iv.Consideration given to overhead services and existing structures when siting pump; 7 Pumping concrete (Pump Operator) Operator competency; Pump planning; High pressures; Incident due to use of defective hoses / equipment; Concrete spillage; 4 5 20 HIGH i. Pumping Plan to be completed prior to any pour taking place by Temporary Works Coordinator; ii. Method statements and risk assessments to be submitted and adhered to; iii. Pump load indicator to be functioning correctly, and not to be overridden under any circumstances; iv. Operator to adhere to safe working load limits; v. Daily inspections of hoses, pipes, connections etc. prior to use. Damaged equipment immediately removed from service; vi. Pump hopper guards to be in place at all times; vii. Plastic sheeting placed under hopper to contain spills; Machine breakdown Hydraulic fluid spill Machine isolated and quarantined until repaired. Spoil removed and treated as hazardous waste Low 8 Pumping operation supervision Pumping operations around workers; Workers in pump operating radius; Reversing concrete delivery vehicles; Worker struck by delivery vehicle; Hose swinging / spinning uncontrolled; Pump operator unable to see task – high level pumping; Over-sailing of material over live traffic routes; Use of concrete – protective gear; Working on rebar – risk of injury; 3 5 15 High viii. No over-sailing of hose over live traffic routes without road closure; ix. Supervision to undertake visual inspection of all pumping gear and equipment daily; x. Workers to wear correct PPE at all times, nitrile gloves, wellingtons, glasses; xi. Flagmen controlling delivery truck movements; xii. Spotters to direct pump operators at high level in clear view at all times; xiii. All concrete soaked workwear to be removed immediately; xiv. Planks placed on rebar for worker access, clear access maintained; Incident – large concrete spill Work stopped, area cleared and full investigation undertaken Low 9 Dismantling of form- work Works at Height; Manual Handling; Worker competency; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Use of unsupervised or untrained personnel to dismantle formwork; 4 4 16 HIGH i. A dismantling Method Statement shall be produced and approved before dismantling is undertaken, to ensure safe removal; ii. The formwork shall be systematically removed as per approved Method Statement and undertaken by competent persons. No deviation from the Method Statement will be undertaken without prior Temporary Works Coordinator approval; Workers not adhering to procedure; Supervision to constantly monitor workers; Low 10 Striking of false-work Works at Height; Manual Handling; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Use of unsupervised or untrained personnel to strike formwork; 4 4 16 HIGH i. A dismantling Method Statement shall be produced and approved before dismantling is undertaken, to ensure safe removal; ii. The falsework shall be systematically removed as per approved Method Statement and undertaken by competent persons. iii. No deviation from the Method Statement will be undertaken without prior Temporary Works Coordinator approval; Workers not adhering to procedure; Supervision to constantly monitor workers; Low