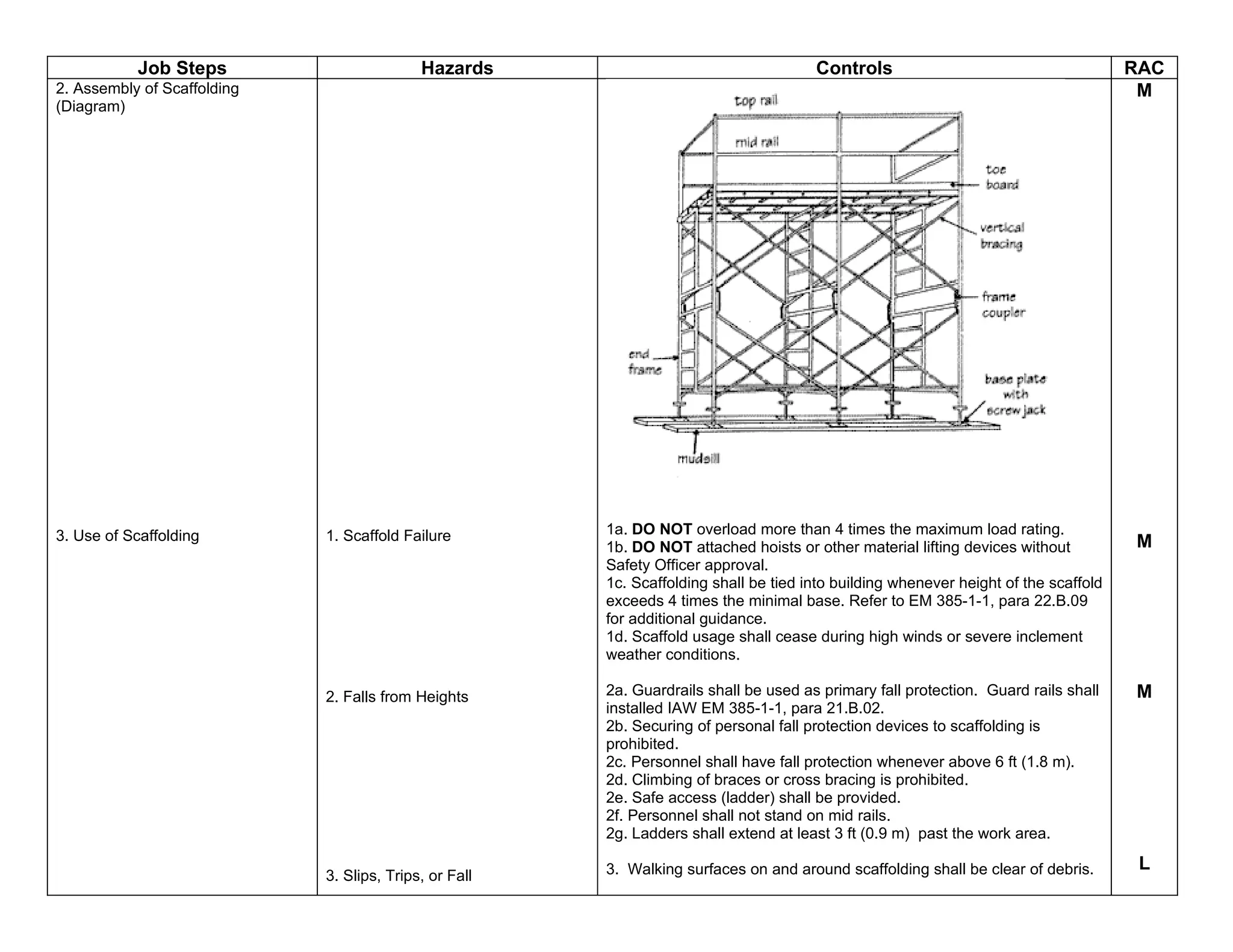

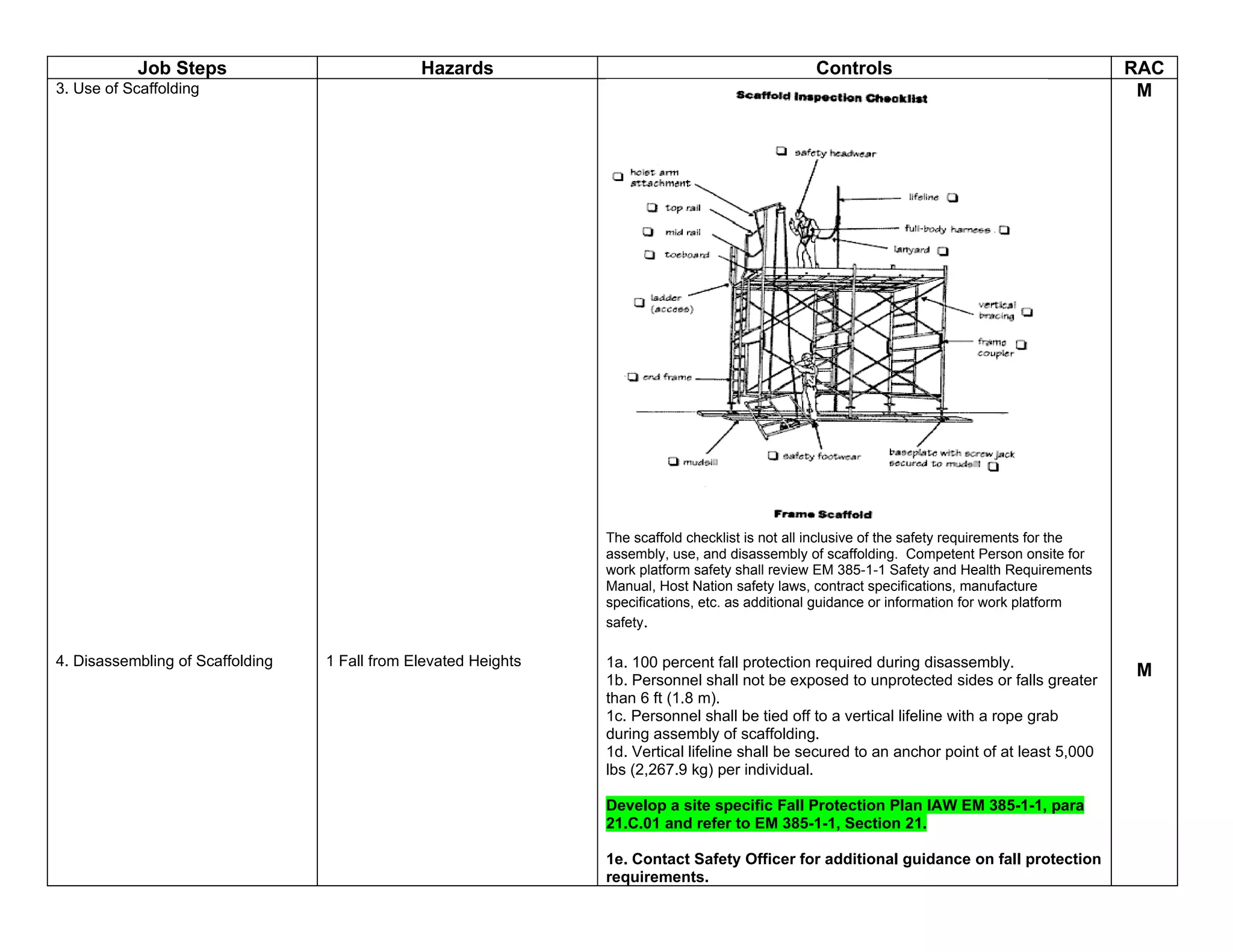

The AHA summarizes the hazards and controls associated with scaffolding erection and use. Key hazards include falls, back strain, lacerations, equipment strikes, and electrical shock. Controls include fall protection, lifting assistance, PPE like gloves, inspecting scaffolding and equipment, and following manufacturer instructions. The overall risk assessment code is moderate due to fall and equipment hazards.