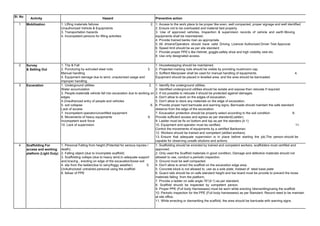

This document outlines safety hazards and preventive measures for various construction activities including mobilization, surveying, excavation, scaffolding, concrete work, and pile breaking. Key hazards addressed include falling, equipment accidents, excavation risks, and improper lifting. Preventive actions emphasize training qualified operators, inspecting equipment, using PPE, designating safety personnel, and following lifting and erection plans. Housekeeping, barricading work areas, and complying with safety standards are also highlighted.