TRA%20of%20Lifting.Tail.docx

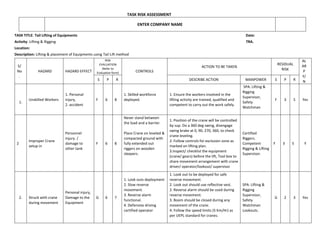

- 1. TASK RISK ASSESSMENT ENTER COMPANY NAME TASK TITLE: Tail Lifting of Equipments Date: Activity: Lifting & Rigging TRA. Location: Description: Lifting & placement of Equipments using Tail Lift method S/ No . HAZARD HAZARD EFFECT RISK EVALUATION (Refer to Evaluation form) CONTROLS ACTION TO BE TAKEN RESIDUAL RISK AL AR P Y/ N S P R DESCRIBE ACTION MANPOWER S P R 1. Unskilled Workers 1. Personal injury, 2. accident F 6 8 1. Skilled workforce deployed. 1. Ensure the workers involved in the lifting activity are trained, qualified and competent to carry out the work safely. SPA: Lifting & Rigging Supervisor, Safety Watchman F 3 5 Yes 2 Improper Crane setup in Personnel injury. / damage to other tank F 6 8 Never stand between the load and a barrier. Place Crane on leveled & compacted ground with fully extended out riggers on wooden sleepers. 1. Position of the crane will be controlled by sup. Do a 360 deg swing, disengage swing brake at 0, 90, 270, 360, to check crane leveling. 2. Follow controls for exclusion zone as marked on lifting plan. 3.Inspect/ checklist the equipment (crane/ gears) before the lift, Tool box to share movement arrangement with crane driver/ operator/lookout/ supervisor Certified Riggers. Competent Rigging & Lifting Supervisor. F 3 5 Y 2. Struck with crane during movement Personal injury, Damage to the Equipment G 6 7 1. Look outs deployment 2. Slow reverse movement. 3. Reverse alarm functional. 4. Defensive driving certified operator 1. Look out to be deployed for safe reverse movement. 2. Look out should use reflective vest. 2. Reverse alarm should be used during reverse movement. 3. Boom should be closed during any movement of the crane. 4. Follow the speed limits (5 Km/Hr) as per UEPL standard for cranes. SPA: Lifting & Rigging Supervisor, Safety Watchman Lookouts. G 2 3 Yes

- 2. 3. Crane collapse due to poor ground condition Property damage, personal injury F 5 7 1. Assess the ground condition prior to lift. 1. Place crane on leveled/compacted ground with fully extended outriggers. 2. Provide wooden pads underneath the float pads of outriggers with area at least 2 times larger than that of float pad area. 4. If the poor ground conditions encountered change the location. 5. In case of soggy conditions do not perform the lift. 6. Don’t setup crane outrigger directly above underground facility. 7. Always provide concrete slabs /ramps for crossing over surface tubing/pipeline. The should be designed so that tubing/pipeline never takes the load upon crane/trailer crossover SPA: Lifting & Rigging Supervisor, Safety Watchman F 3 5 Yes 4. Damaged lifting gears Lifting Collapse, Serious personal injury/Fatality E 4 7 1. Pre Use inspection of lifting accessories & equipments. 2. Check the valid 3rd party certification. 1. Ensure all lifting gears should be third party certified. 2. Inspect all Lifting equipment and accessories before any lifting activity 3. For choking of pipe spools with wire rope sling, ensure proper anchorage with the help of bulldog clamps Check sling angles (with horizontal) are equal to or greater then 45 deg. De-rate WLL of shackles, slings for different angles/configurations/modes For single/double choker reduce the sling SWL by 20%. SPA: Lifting & Rigging Supervisor, Safety Watchman E 2 5 Yes 5. Falling / Slipping of load Physical Injury, Load Hit with Existing Piping. G 6 7 Lifting plan, Weight of load should be known, Trail Lift Slowly raise / lower the load, Lifting plan should be available at site Lifting gear certification, trial lift. 2.Rigging study should be available at job site Safety Supervisor, Rigger, Banks man, Supervisor G 2 3 Yes 6. Unnecessary movement of personnel Personal Injury G 6 7 1.Area cordon off 2.No parallel activities 1. Area to be cordoned off with full time supervision. 2. Stop other activities in that working area. Safety Supervisor, Banks man G 2 3 Yes 7. Weather conditions Equipment stuck in muddy area due to rain, High Wind speed F 5 7 1.Site/area/location survey before moving equipment at site i.e. Soil condition 1. Rigger/signal/outlook man visit site before moving equipment at site. 2. HSE supervisor will ensure wind speed limit before starting lifting operation if wind speed exceeds from 25 knots TRA should be revised. Rigging Sup,(SPA) Crane Opt, HSE Sup F 3 5 Yes

- 3. 2.Wait till clear visibility achieved (in case of wind storm) 3. Observe plant wind speed limit before any lifting operations. 3. No lifting if wind speed cross 30 knots 4. Wind speed Reading should be from radio room or look out for wind sock. Wind sock generally gets horizontal if wind speeds are equal to or above 15 knots. 8. SIMPOS Injuries, Fatalities E 7 10 Cross reference this task with all relevant PTW's, plans certificates one day before job execution subject to SIMPOS operation Conduct a permit planning meeting with stakeholders one day before job execution Stop all SIMOP activities that fall within the barricaded area of crane Rigging Sup, Crane Operator, Safety Watch E 2 5 Yes 9 Crane Overload Crane Toppling, Structural Failure, Damage to other tank, Personnel injury/fatality F 6 8 Tool box talk sharing the sequence of lift as mentioned in lifting plan, load chart, Check the calibration of SLI prior to lift. Define exclusion zone Check work radius prior to lift see if they tally with the lifting plan, in case of any variation reposition the crane. Perform trial lift (inch the load to check stability and verify the weight of the load with SLI) in accordance with the lift plan. Keep everyone out of the exclusion zone. Competent Lifting Supervisor, Certified riggers Safety watch (spotters) F 4 6 Y 10 Inadequate or inoperative safety devices Equipment damage due to overload, Plant/facility damage G 6 8 Perform functional test of mobile crane, verify SLI readouts with proper tools Check whether ATB is working (audible alarm and cut-off) Verify SLI boom angle readout with angle finder, Radius readout with measuring tape, boom length with load chart (main boom), actual load with crane hook load or if possible test load prior to lift. Check whether correct falls are selected on SLI display. Crane operator, Rigging and Lifting Supervisor G 4 5 Y GENERAL COMMENTS: Abbreviations 1. TBT will be conducted prior to job start. SPA: Single Person Accountable 2. Unauthorized entry of the person not allowed in work premises. ATB: Anti-Block 3. PPE’s should be use (safety helmet, goggle, gloves, safety shoes ,safety harness, Face shield, welding helmet, SWL: Safe Working Load Welding gloves,) SLI: Safe Load Indicator 4. Stand by vehicle must be present at the site in case of emergency. SIMOPS: Simultaneous Operation 5. Adequate cold drinking water readily is available at the site to prevent dehydration. 6. Housekeeping of the area should be done on prior basis before and after completion of job. NAME OF TEAM MEMBERS ( Manager) (Rigging & Lifting Supervisor) (Hse Engineer/officer) Signature RISK ASSISMENT APPROVAL I’m satisfied that the safeguard put in place will reduce the level of Risk to an acceptable level and the Task/Action is permitted to proceed. Reviewed by: ____________ Date: ________________________ Time: ____________________

- 4. S = Severity; P = Probability, R = Risk Authorizing Signatory: _______________ DATE: ________________