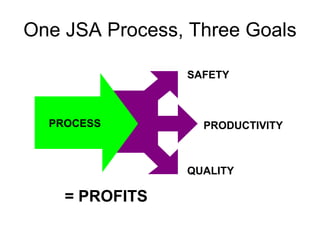

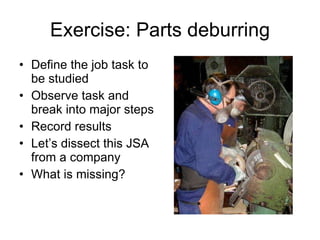

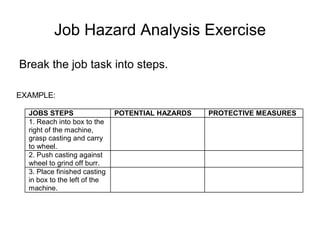

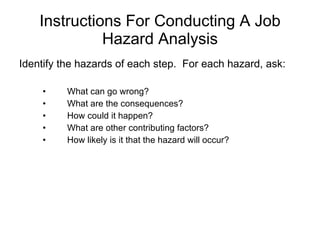

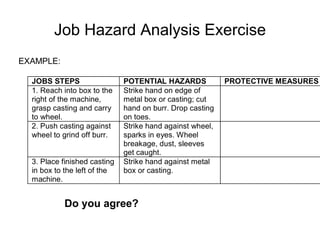

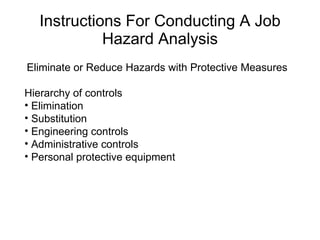

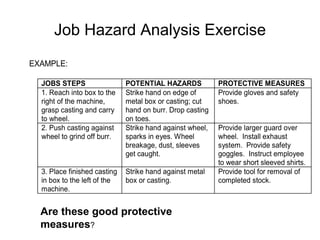

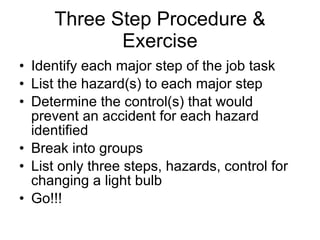

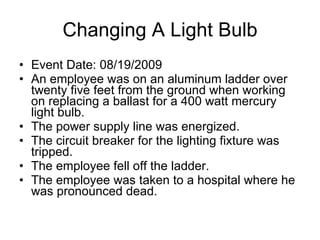

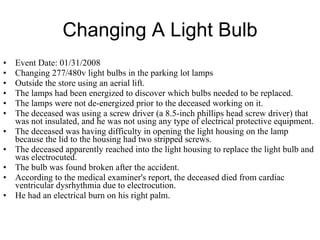

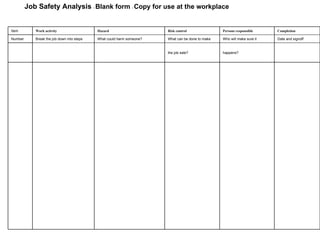

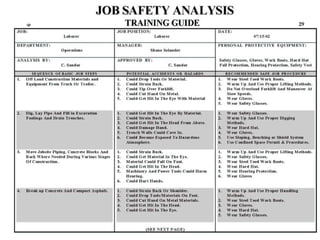

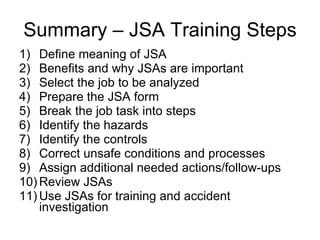

The document discusses job safety analysis (JSA) training. It defines JSA as a method to break jobs into steps and identify hazards and controls. It explains that JSA identifies unsafe practices, decreases injuries, increases quality and productivity. The training objectives are to explain the need for JSA, benefits, how to complete them, and provide the necessary tools. The document also provides examples of completing a JSA and emphasizes employee involvement.

![No JSA = Bad The report found that risk assessment was “often incomplete,” that business units did not understand or address major hazards, and that competency in risk and hazard assessment was poor. BP March 2004 audit finding. “Many [people] reported errors due to a lack of time for job analysis, lack of adequate staffing, a lack of supervisor staffing, or a lack of resident knowledge of the unit in the supervisory staff.” 2005 Telus survey](https://image.slidesharecdn.com/jsa2010-100420115716-phpapp01/85/Job-Safety-Analysis-6-320.jpg)

![Contact John Newquist 230 S Dearborn, Ste 3244, Chicago IL 60604 [email_address] 312-353-5977](https://image.slidesharecdn.com/jsa2010-100420115716-phpapp01/85/Job-Safety-Analysis-35-320.jpg)