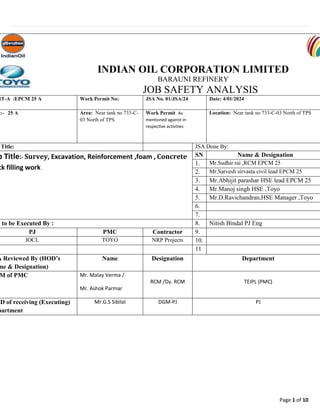

This document provides a job safety analysis for excavation, reinforcement, and concrete pouring work near tank no. 733-C-03. It identifies several hazards associated with the work including slips/trips/falls, contact with sharp edges, collision with vehicles, hazardous atmospheres in excavations, collapse of excavation edges, and more. For each hazard, it recommends control measures such as using personal protective equipment, barricading work areas, ensuring adequate slopes in excavations, permitting for confined space and excavation work, and conducting toolbox talks and inspections. The analysis was conducted by an 11-person team including representatives from IOCL, Toyo, and PMC and was reviewed by heads of relevant departments.