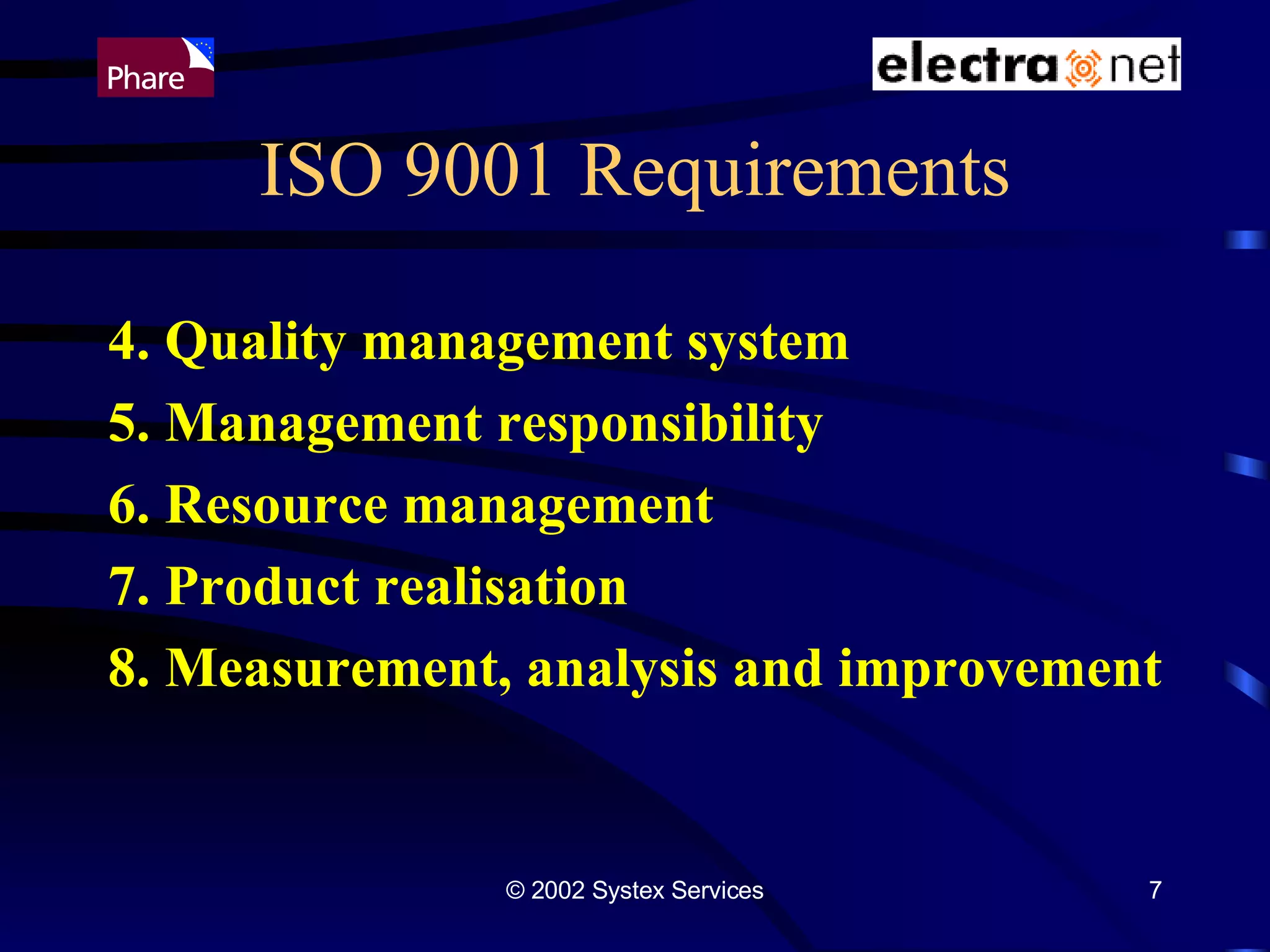

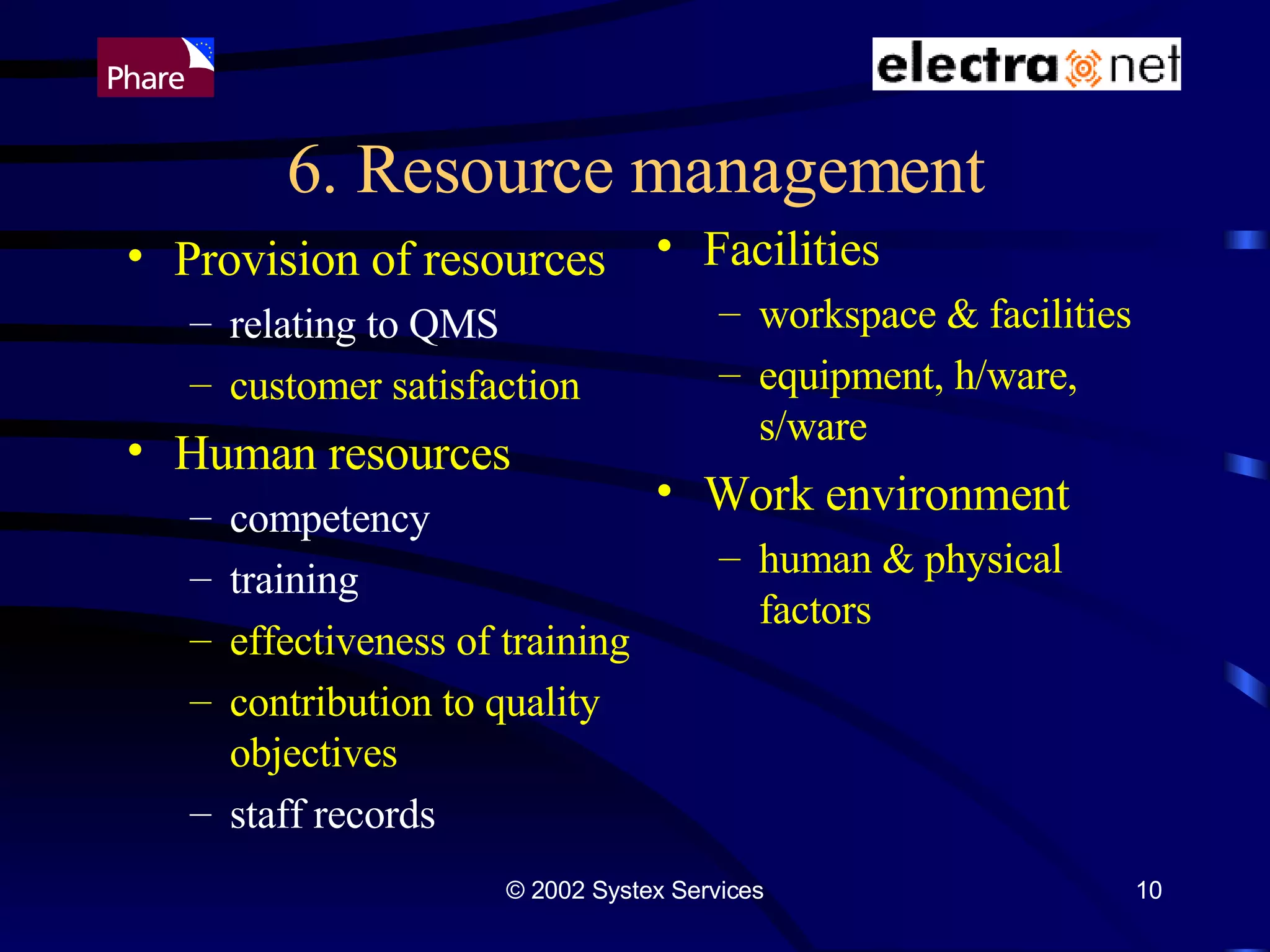

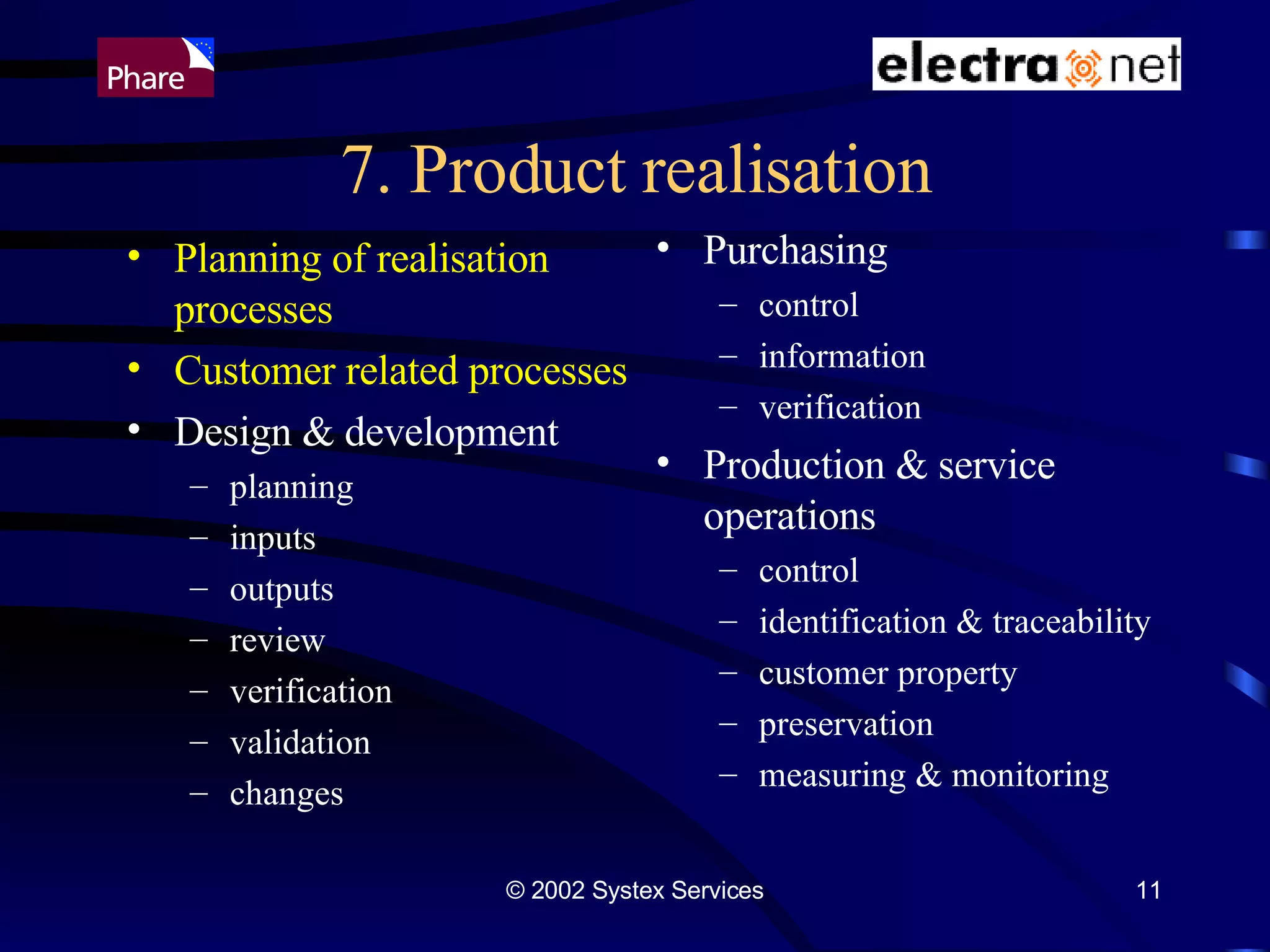

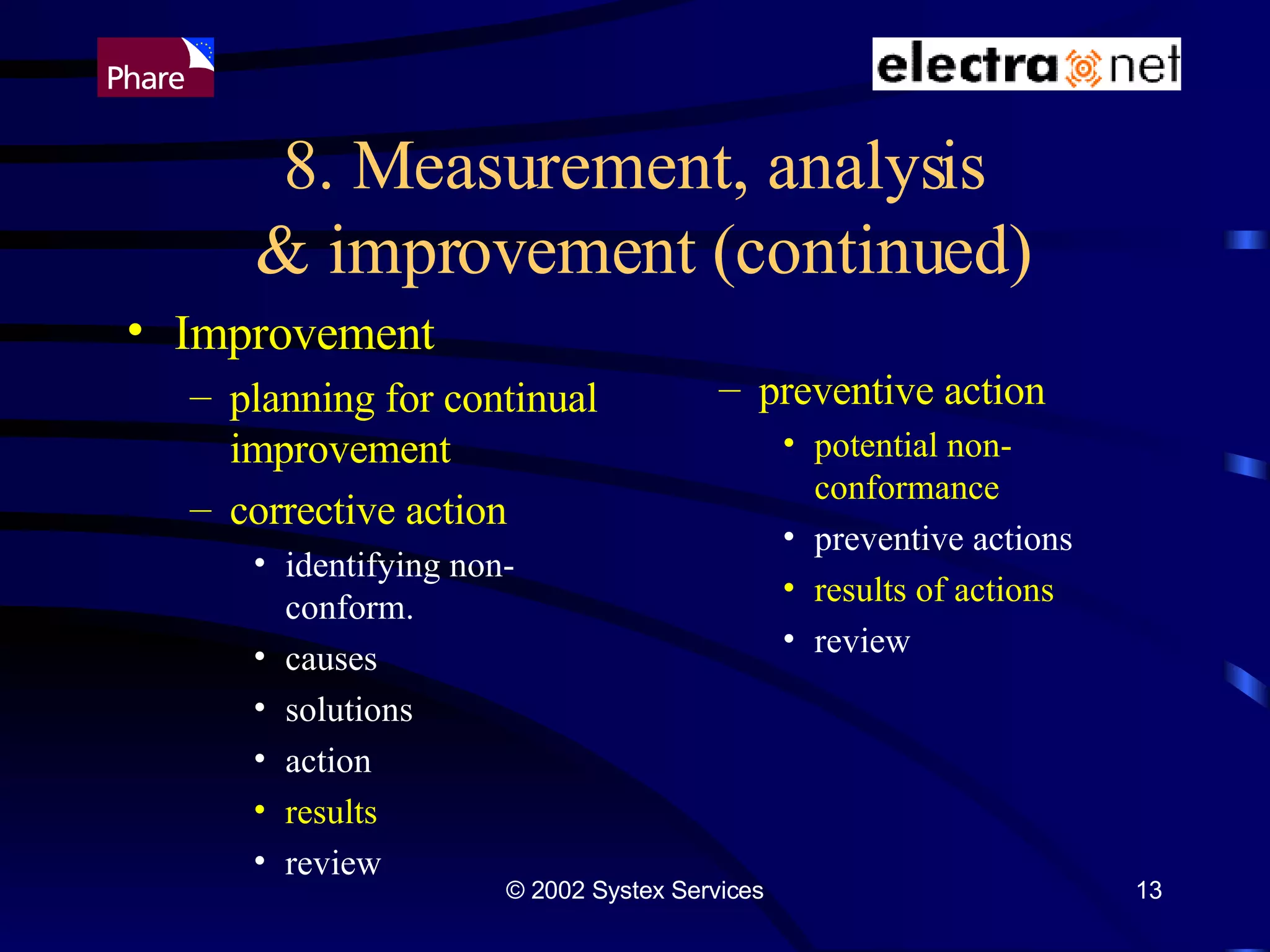

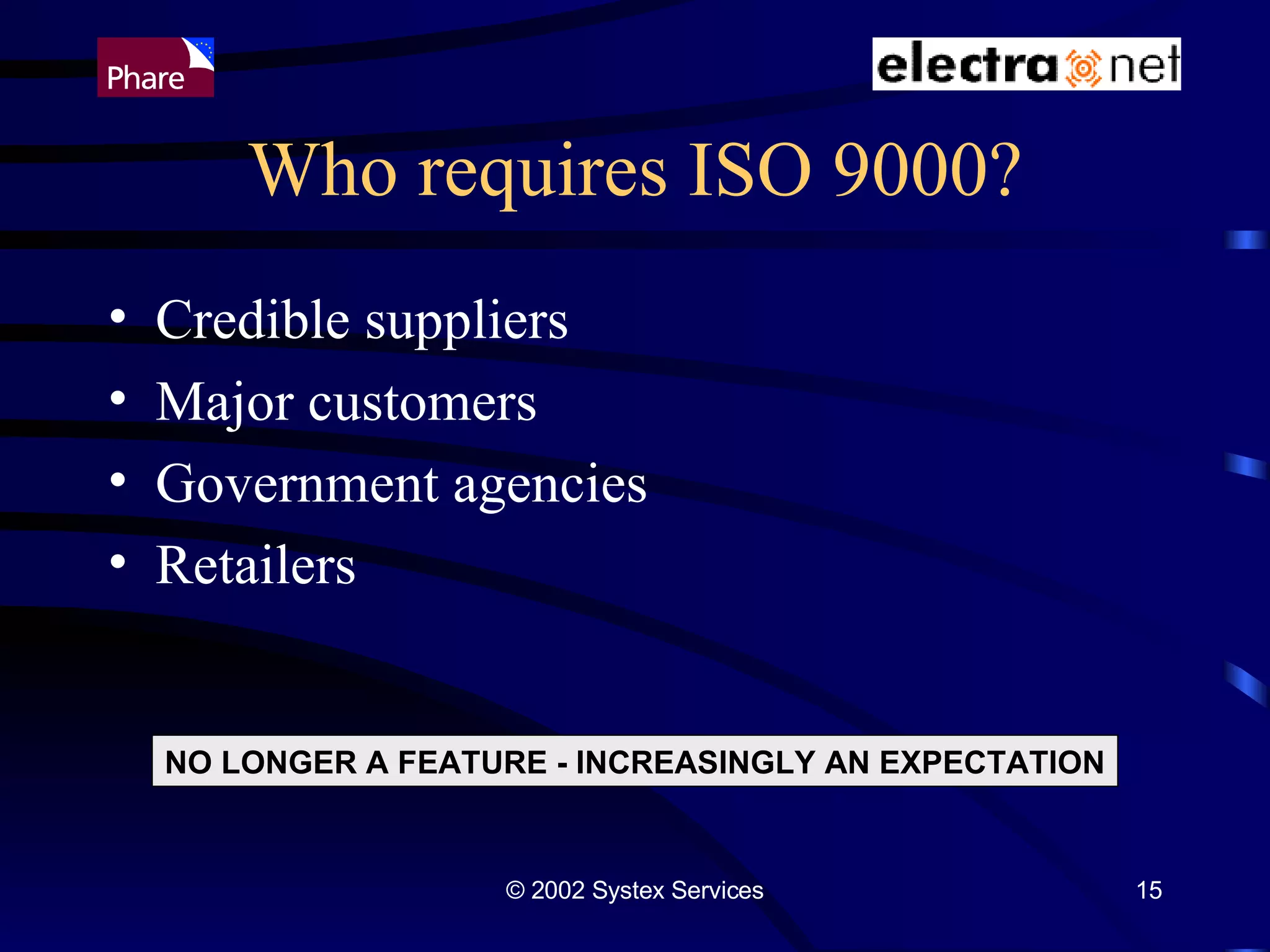

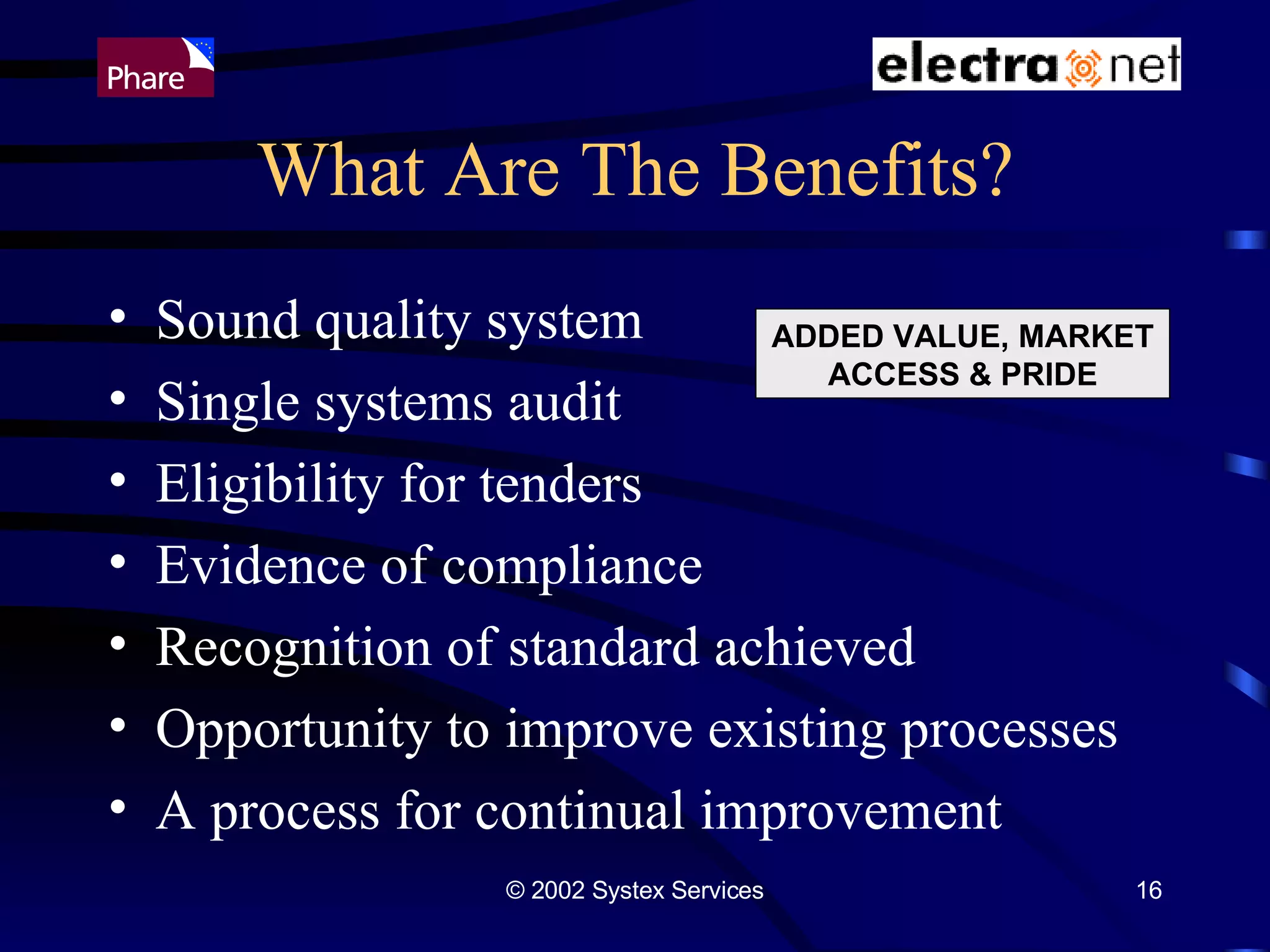

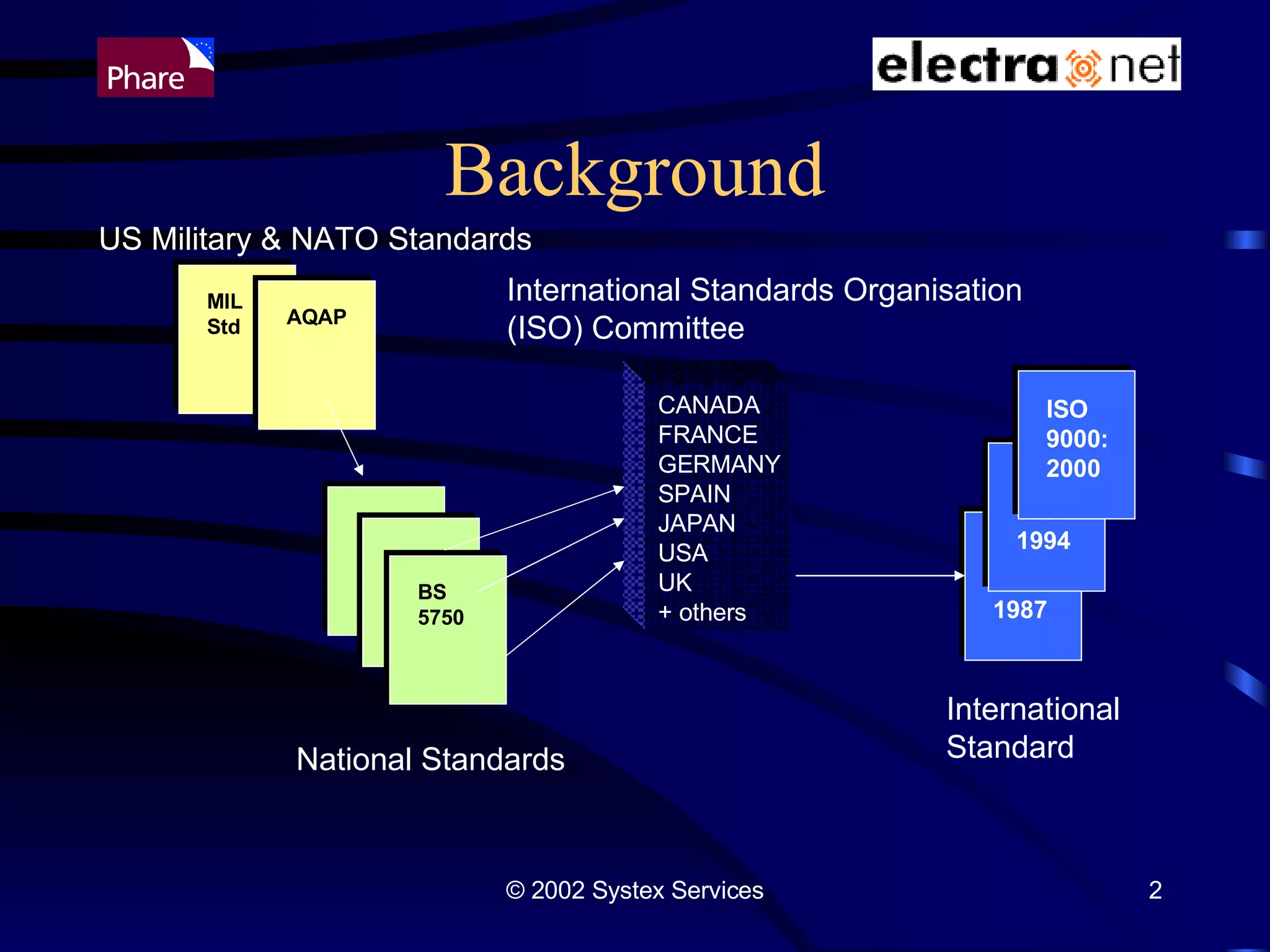

The document outlines ISO 9000, an internationally recognized quality management system. It provides a brief history of quality standards that preceded ISO 9000 and describes the development and components of the ISO 9000 series. The key requirements of an ISO 9000-compliant quality management system are management responsibility, resource management, product realization, measurement, analysis and improvement. Certification involves preparing documentation and procedures, internal audits, and an external assessment.

![What is ISO 9000? [1] ISO 9000 is an internationally recognised quality management system developed by ISO (International Organisation for Standardisation) UNIVERSALLY RECOGNISED - SOUND QUALITY SYSTEM](https://image.slidesharecdn.com/iso-9000-2000-outline2850/75/ISO-9000-2000-Outline-3-2048.jpg)

![What Is ISO 9000? [2] ISO 9000 Series ISO 9000 : 2000 QUALITY MANAGEMENT SYSTEMS - Fundamentals and vocabulary - supersedes ISO 8402 and ISO 9000-1:1994 ISO 9001: 2000 QUALITY MANAGEMENT SYSTEMS - Requirements - supersedes ISO 9001/2/3:1994 ISO 19011: 2002 Guidelines on auditing quality and environmental management systems - supersedes ISO 19011:1994 ISO 9004 : 2000 QUALITY MANAGEMENT SYSTEMS - Guidelines for improvement - supersedes ISO 9004-1](https://image.slidesharecdn.com/iso-9000-2000-outline2850/75/ISO-9000-2000-Outline-4-2048.jpg)

![What Is ISO 9000? [3] Standard based on 8 quality management principles customer focus leadership involvement of people process approach system approach to management continual improvement factual approach to decision making mutually beneficial supplier relationships](https://image.slidesharecdn.com/iso-9000-2000-outline2850/75/ISO-9000-2000-Outline-5-2048.jpg)