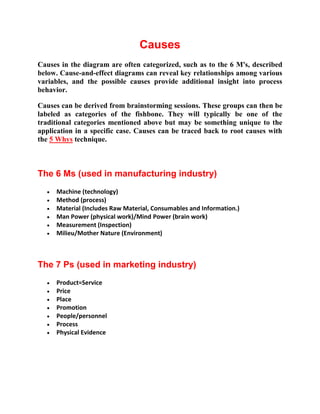

The document discusses Ishikawa diagrams, also known as fishbone diagrams or cause-and-effect diagrams. These diagrams were created by Kaoru Ishikawa to show the potential causes for a specific event or problem. The diagram takes the shape of a fishbone, with major categories of causes branching off from the problem. Common categories include people, methods, machines, materials, measurements, and environment. The document provides examples of categorizations used in different industries and discusses how the diagrams can help identify root causes through brainstorming.

![The 5 Ss (used in service industry)

Samples

Scheme

Synchronous

Skin

Search

5 W

Where

What

When

Who

Why

Criticism

In a discussion of the nature of a cause it is customary to distinguish between necessary and

sufficient conditions for the occurrence of an event. A necessary condition for the

occurrence of a specified event is a circumstance in whose absence the event cannot occur.

A sufficient set of conditions is a situation/circumstance in whose presence the event must

occur.[5]

Ishikawa diagrams have been criticized for failing to make the distinction between

necessary conditions and sufficient conditions. It seems that Ishikawa was not even aware

of this distinction.[6]](https://image.slidesharecdn.com/ishikawadiagram-130805225140-phpapp02/85/Ishikawa-diagram-4-320.jpg)