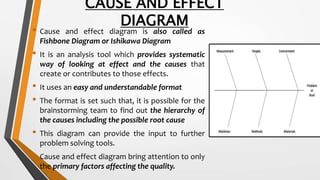

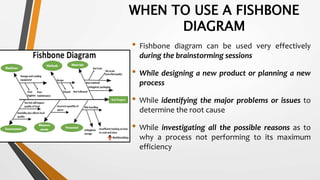

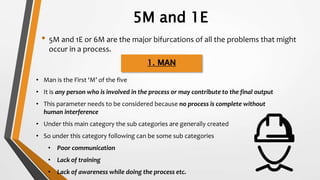

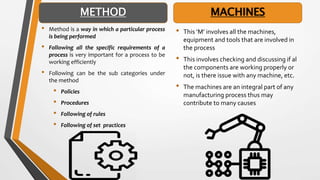

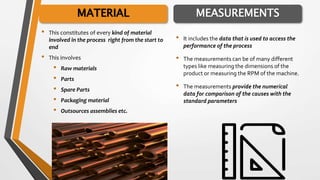

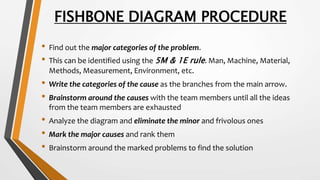

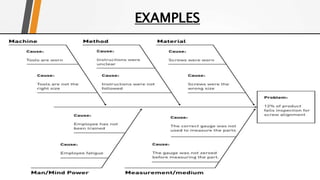

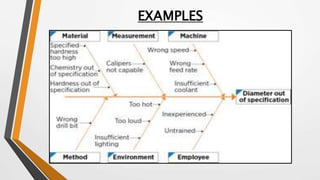

The cause and effect diagram, also known as the fishbone or Ishikawa diagram, is an analytical tool used to systematically identify and analyze the root causes of an effect or problem. It is beneficial during brainstorming sessions, product design, and process planning, categorizing issues into major factors such as man, method, machine, material, measurement, and environment. The diagram enhances teamwork and understanding, making it easier to pinpoint solutions to identified problems.