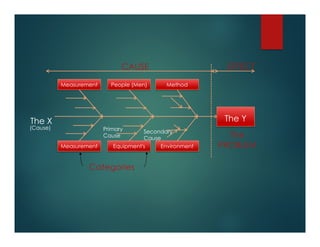

The document discusses cause and effect diagrams, also known as fishbone diagrams. It begins by defining cause and effect diagrams as visual problem-solving tools used to identify the causes of problems in relation to their effects or observed results. It then discusses that Kaoru Ishikawa, a Japanese quality expert, invented the fishbone diagram in 1943 to help engineers understand complex factor relationships. The major purpose of cause and effect diagrams is to generate a comprehensive list of possible causes as an initial step in problem-solving. Finally, it discusses that possible causes can be categorized into sources like measurement, method, people, materials, equipment, and environment when using a fishbone diagram.