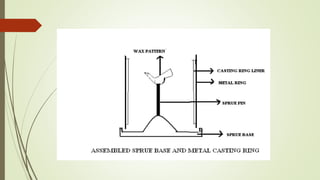

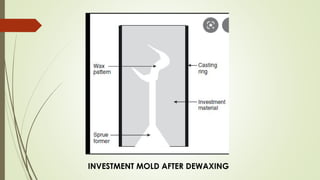

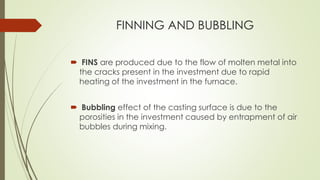

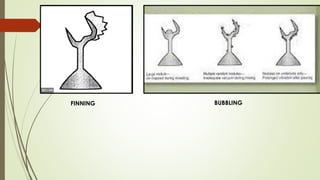

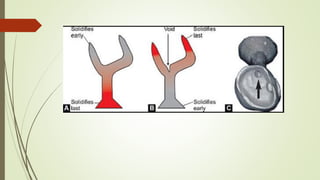

The document outlines the casting procedure in dental materials which includes forming a wax pattern, investing it, and casting molten metal into the mold. Key factors influencing casting quality include the sprue size, length, and position, as well as methods for investing and eliminating wax patterns. Common casting defects such as porosity, incomplete casting, and size discrepancies are also discussed.