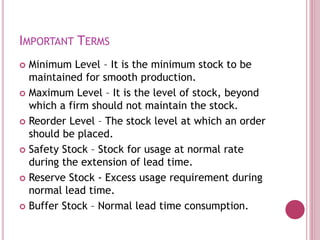

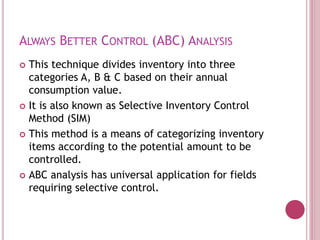

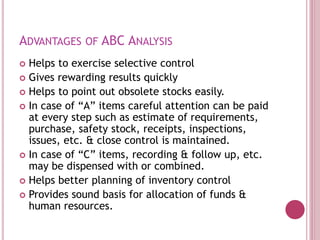

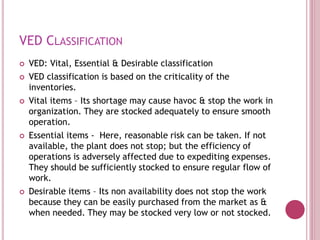

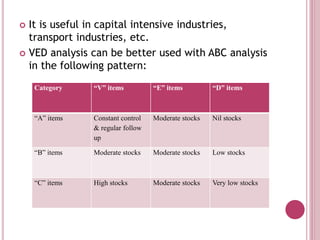

This document discusses various inventory control systems used to classify inventory items. It introduces the Always Better Control (ABC) analysis technique which divides inventory into categories A, B and C based on their annual consumption value. Items in category A have the highest value and require the most control. The Vital-Essential-Desirable (VED) and Fast-Slow-Non moving (FSN) analyses also classify inventory based on criticality and pattern of issues, respectively, to determine appropriate stocking levels. The document provides procedures and benefits of these selective inventory control methods.