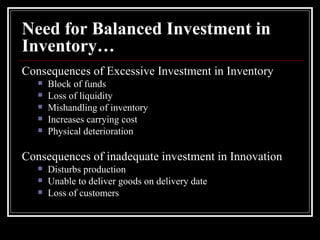

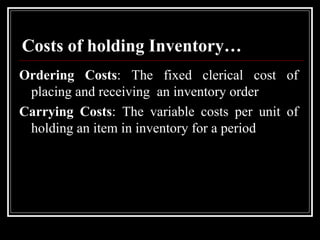

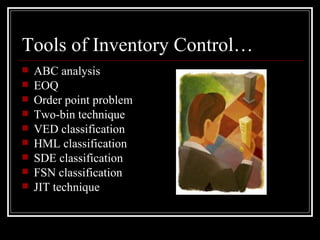

This document discusses inventory management techniques for businesses. It covers the need to balance inventory levels to ensure continuous production while minimizing costs. It describes different inventory control methods like ABC analysis, economic order quantity models, order points, and safety stock. It also lists the various costs of holding too much or too little inventory such as carrying costs, opportunity costs, and risks of price changes or obsolescence.