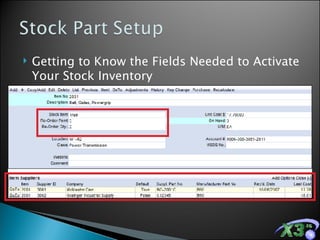

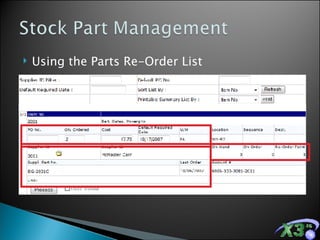

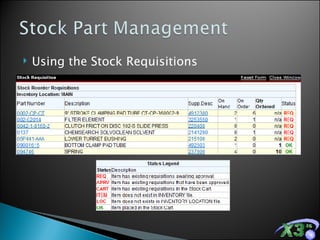

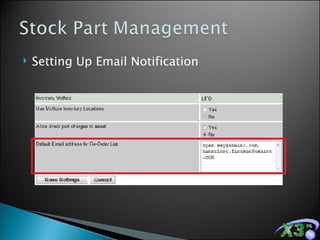

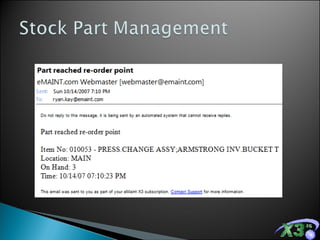

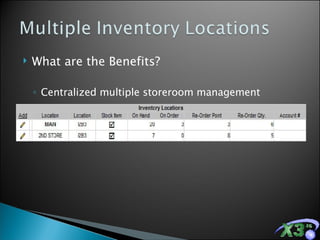

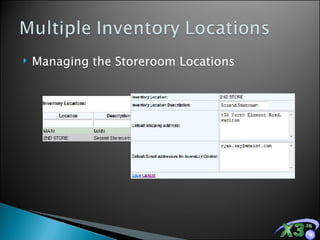

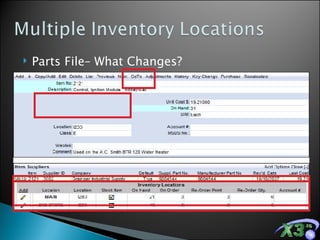

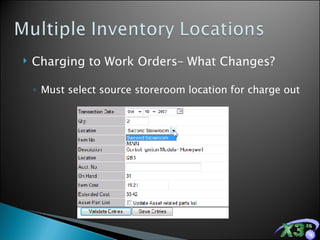

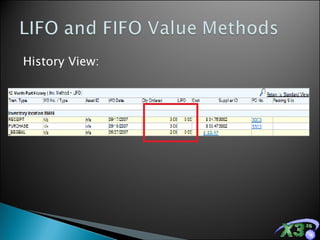

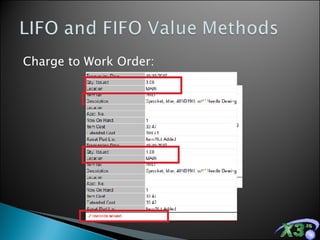

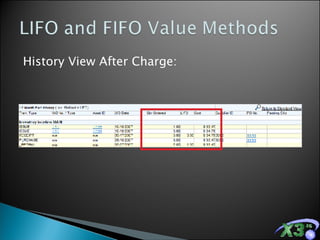

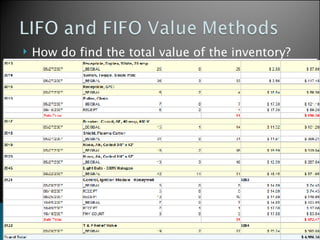

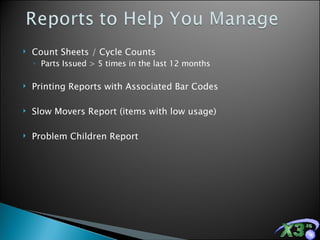

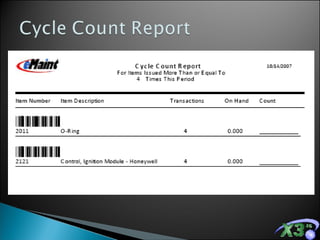

The document discusses inventory management features in the X3 software. It outlines tools for setting up and managing stock parts across multiple locations, inventory valuation methods, and mobile inventory control. Benefits of effective inventory management include minimizing downtime and expedited shipping costs. The document then describes specific X3 features for inventory control, including reorder lists, stock requisitions, notification settings, and inventory reports. It also discusses integration options between X3 and other applications.