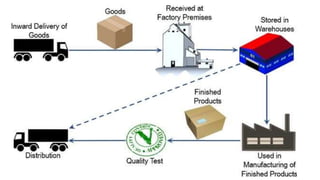

This document provides information on inventory and inventory management. It defines inventory as items, parts, and materials that companies use in production or sell. The document then discusses different types of inventory like raw materials, work in progress, finished goods, and safety stock. It explains that inventory management aims to ensure sufficient stock while avoiding excess inventory that can become a liability. The document outlines objectives of inventory management like preventing waste and optimizing costs. It also discusses the importance of inventory management in enabling ERP systems and efficient supply chain management.