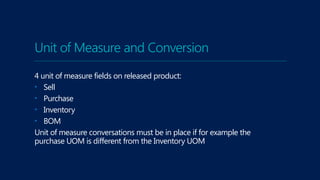

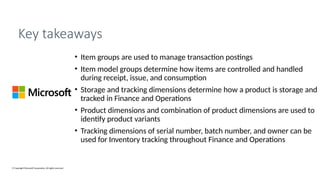

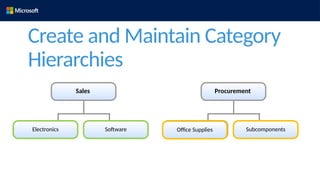

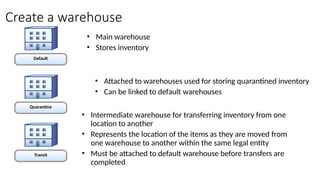

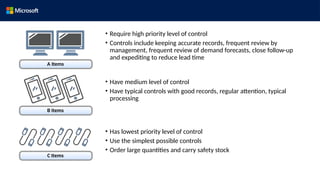

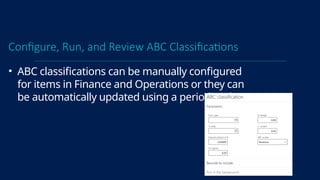

This document provides a comprehensive guide on configuring and managing products and inventory in Microsoft Dynamics 365 for Finance and Operations, covering aspects such as item and dimension groups, inventory management, and reporting. Key functionalities include setup for inventory journals, management of transfer orders, and utilization of the ABC classification system to prioritize inventory control. Additionally, it outlines inventory tracking, product attributes, and the creation of warehouse structures to facilitate smooth operations and reporting.