The document discusses several key concepts in lean manufacturing including:

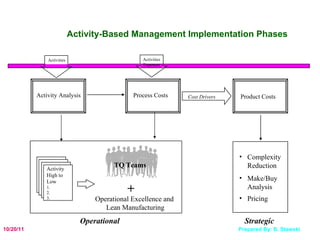

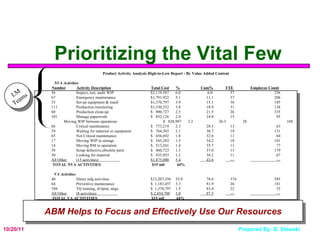

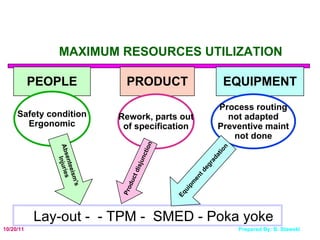

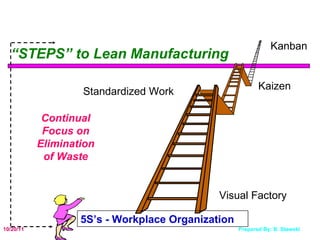

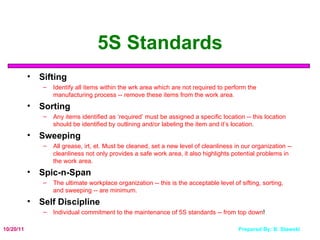

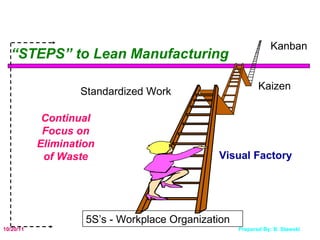

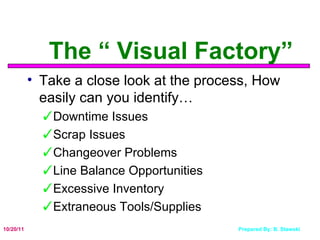

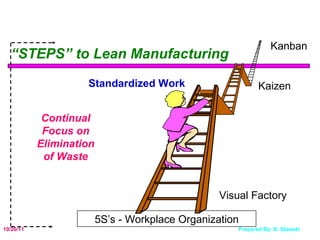

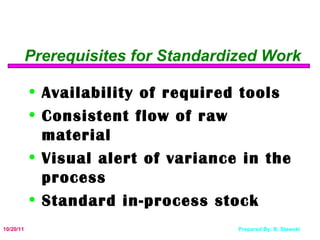

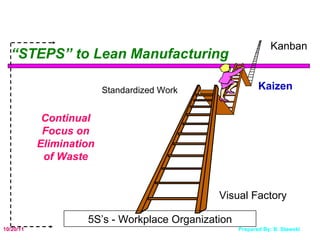

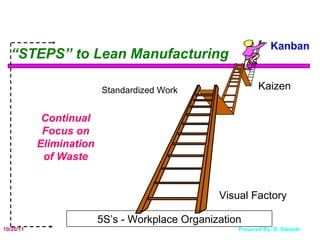

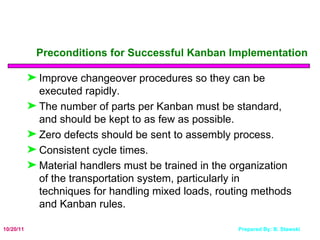

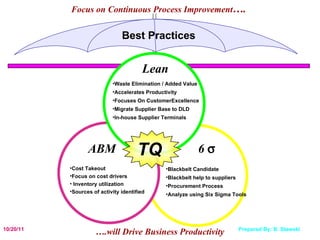

1. The goal of lean is to identify and eliminate waste in the production system through techniques like 5S, standardized work, visual management, and kanban pull systems.

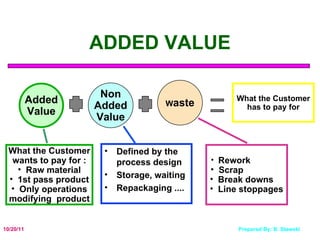

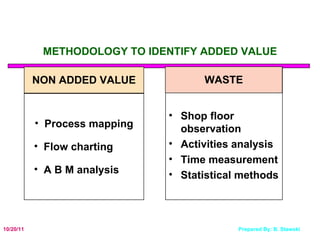

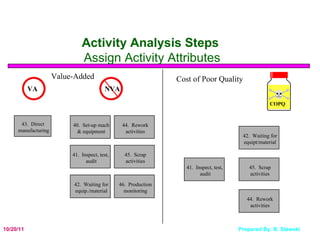

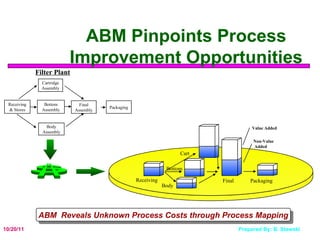

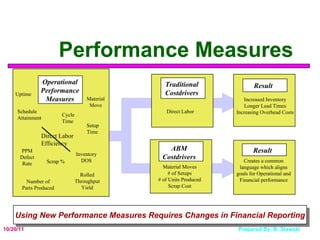

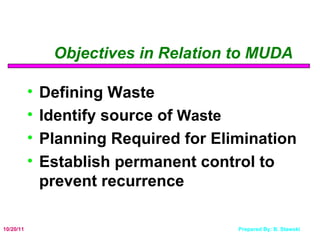

2. Value-added activities are those that customers are willing to pay for, while non-value added activities are waste that does not contribute to the product.

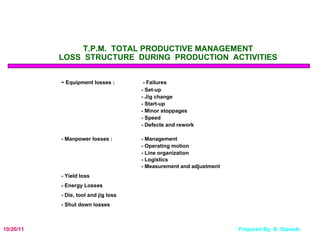

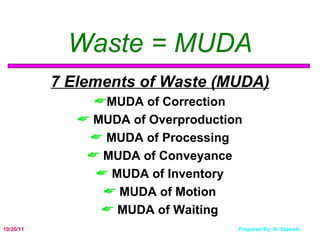

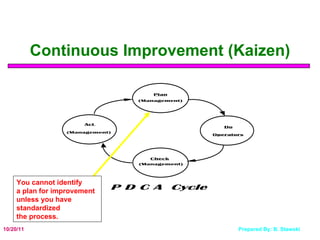

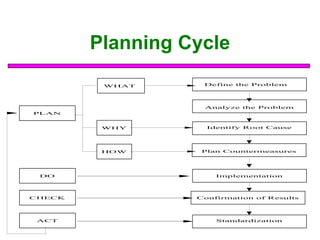

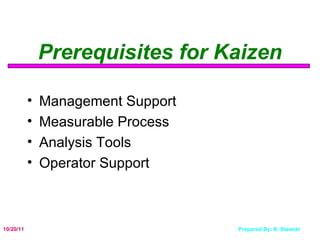

3. The seven types of waste or "muda" are overproduction, waiting, transportation, overprocessing, inventory, motion, and defects. Methods like kaizen aim to continuously eliminate these forms of waste.