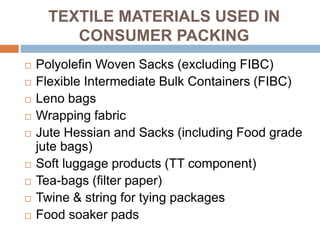

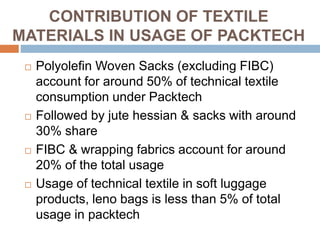

The document discusses packaging textiles, highlighting their importance in containing, carrying, storing, and protecting goods. It details various types of textile materials used in packaging, including polyolefin woven sacks, flexible intermediate bulk containers, jute sacks, and more, as well as their applications and advantages. The text emphasizes the growing demand for eco-friendly and reusable packaging solutions within the technical textiles sector.

![REFERENCES

[1]http://www.companiesandmarkets.com/MarketInsight/Textiles-and-

Clothing/TechnicalTextiles-Market/NI6995.

[2]https://www.textilesintelligence.com/tisttm/index.com.

[3] http://www.technicaltextile.net/packaging-textiles/

[4] http://www.bch.in/index.html

[5]http://butekom.com/docs/sunumlar/2013.10.09_Teknik_Tekstil/Ambalaj_Tek

stilleriAli_Ruzgar.pdf

[6] http://textilelearner.blogspot.com.tr/2013/01/packtech-textile-packaging-

material.html

[7]Horrocks, A.R., Anand, S.C., 2000, Handbook of Technical Textiles,

Woodhead Publishing Series in Textiles No. 12, UK](https://image.slidesharecdn.com/1526563236837packagingtextiles-190308172629/85/Packaging-textiles-18-320.jpg)