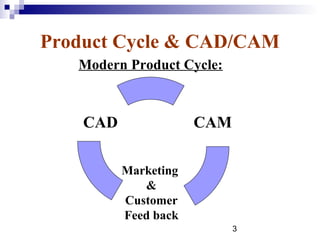

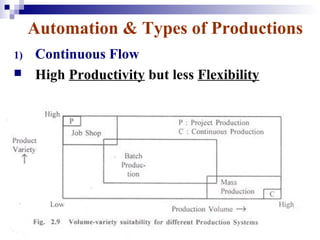

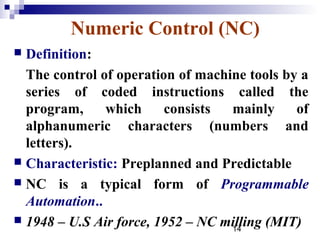

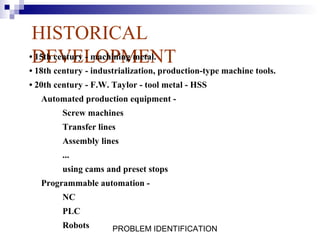

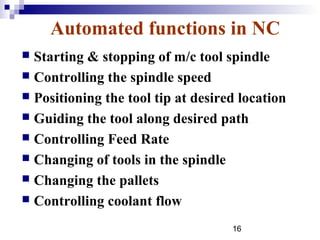

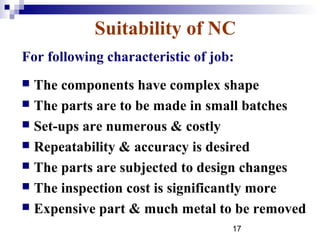

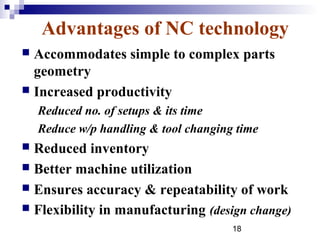

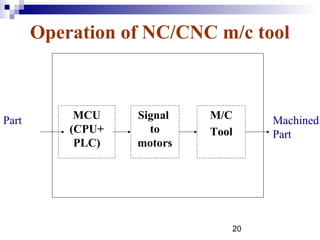

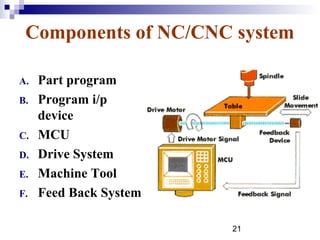

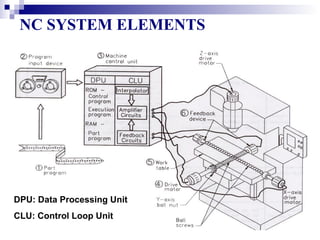

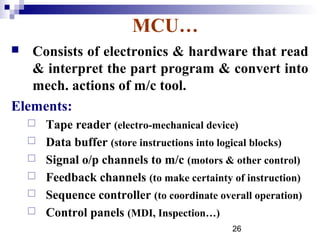

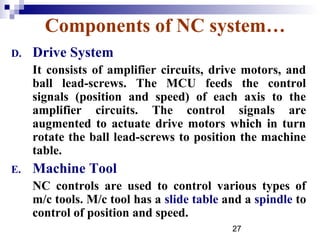

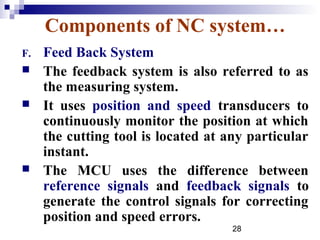

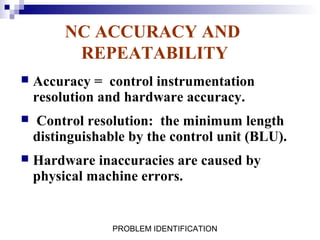

The document discusses computer-aided manufacturing (CAM) and numeric control (NC) technology, including definitions of CAM and NC, the components and operation of NC/CNC systems, the advantages of CAM and NC, different types of production processes, and historical developments in automation and programmable machine control.