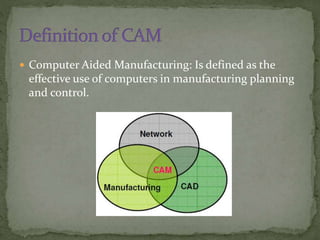

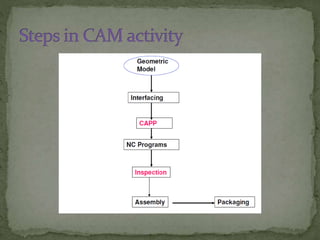

The document discusses CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing). It explains that CAD is used to design a part which is then used by CAM to generate tool paths for CNC machine tools. Both CAD and CAM functions can be performed by the same or separate systems. CAD designs are exported to CAM systems which assist in all phases of manufacturing. The integration of CAD and CAM automates the process and links product design to manufacturing.