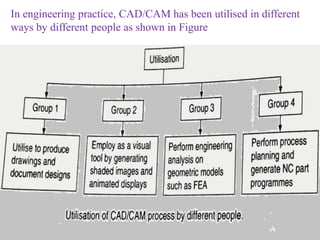

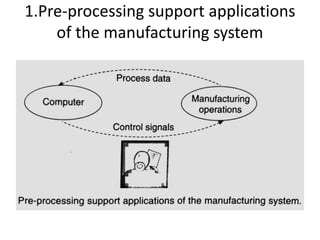

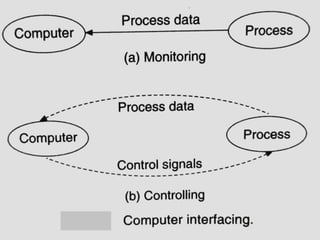

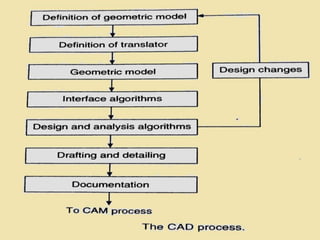

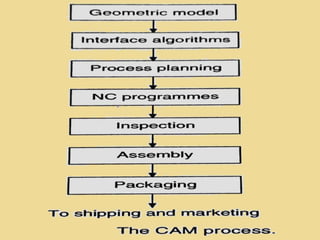

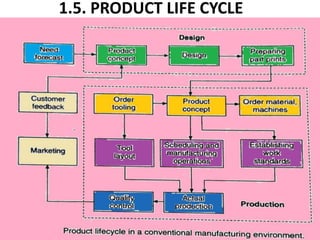

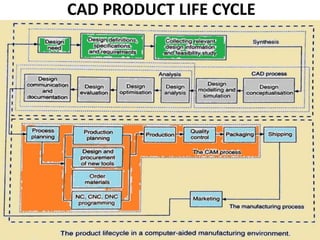

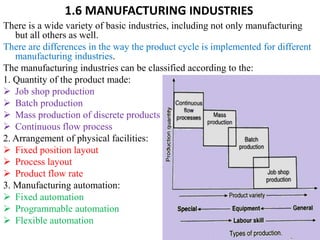

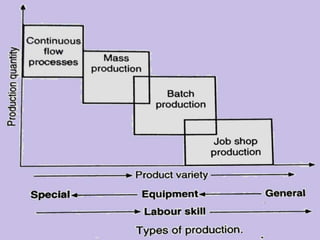

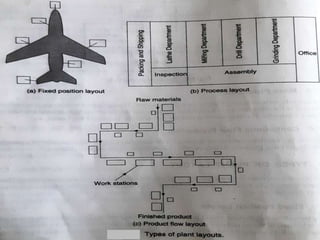

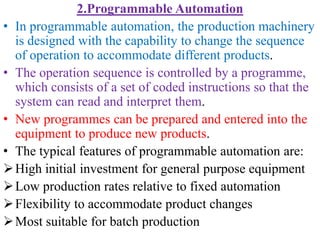

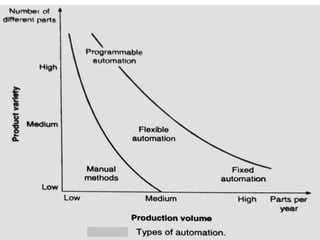

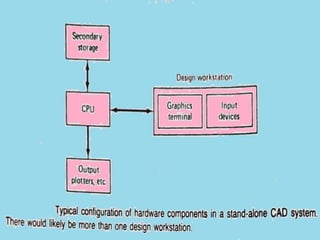

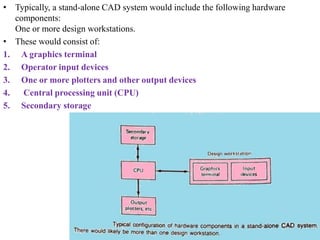

The document outlines the course CAD & CAM for B.Tech students, detailing pre-requisites, objectives, and outcomes including geometric modeling, CNC programming, and integration of CAD/CAM in manufacturing processes. It further discusses the roles of computer-aided design and manufacturing, the significance of historical figures like Patrick J. Hanratty and Pierre Etienne Bezier, and the importance of product life cycles and types of production in manufacturing. Additionally, it covers the methodologies involved in integrating computers into production systems, emphasizing their impact on efficiency and cost management.