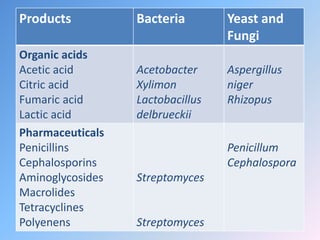

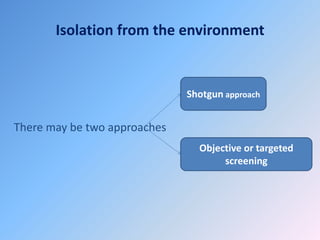

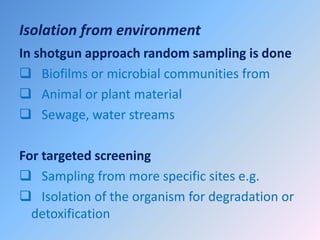

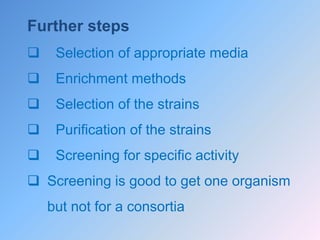

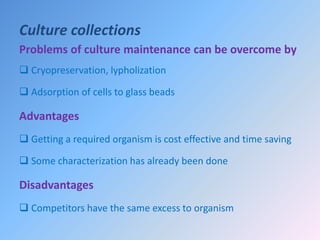

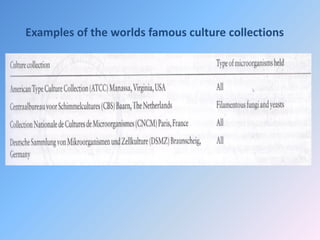

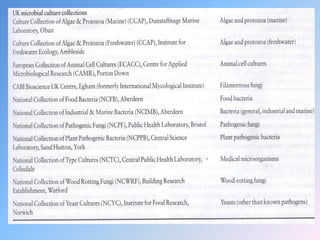

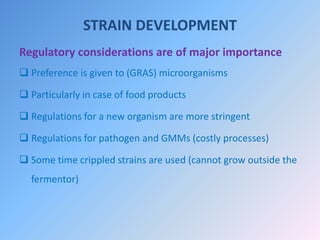

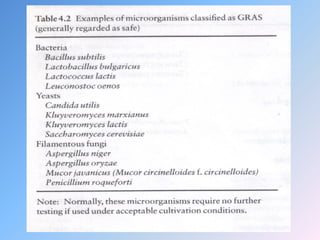

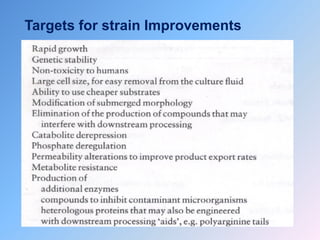

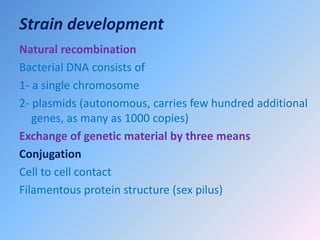

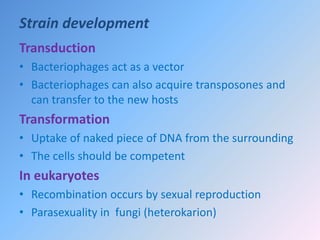

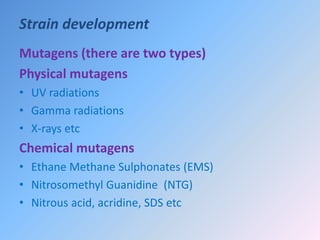

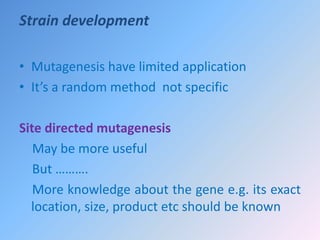

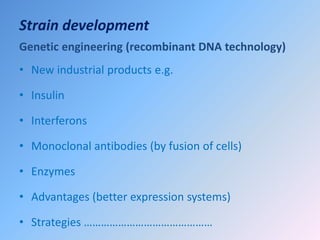

This document discusses strain improvement strategies for developing microorganisms used in industrial fermentation. It describes obtaining strains from environmental screening or culture collections, and then improving strains through natural recombination, mutagenesis, or recombinant DNA techniques. The key strategies discussed are natural genetic exchange between microbes, physical and chemical mutagenesis to generate random mutations, and directed genetic engineering using recombinant DNA technology to develop strains with desired properties like high product yields or utilization of low-cost substrates. The goal is to obtain stable, high-producing industrial microorganisms.