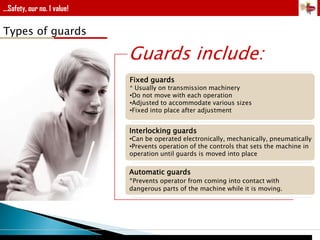

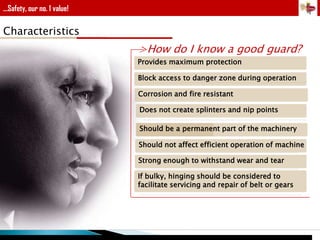

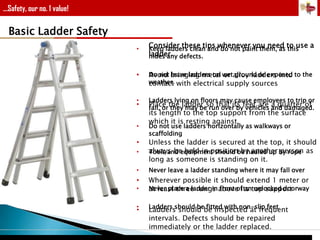

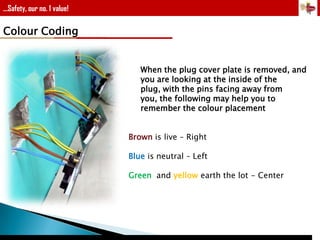

The document discusses various topics relating to industrial safety, with a focus on electrical safety. It provides guidance on machine guarding, lock-out procedures, personal protective equipment, handling compressed gas cylinders, working with air compressors, and basic electrical safety checks. The document emphasizes that safety should be the top priority in all industrial operations and maintenance work. Proper training and adherence to safety protocols can help prevent accidents and protect workers.