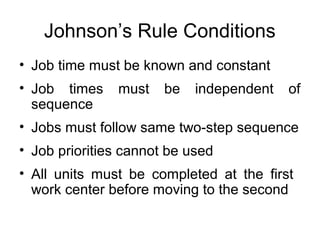

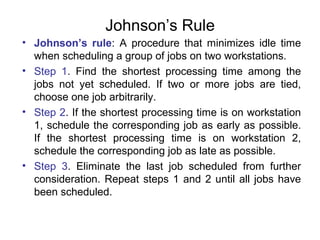

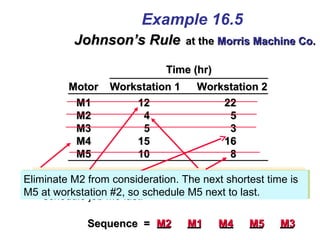

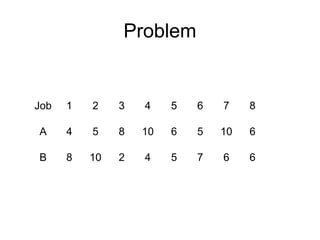

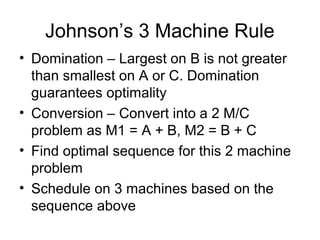

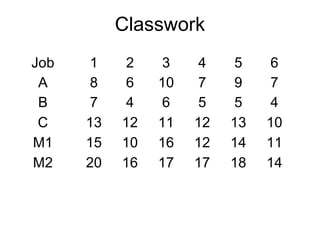

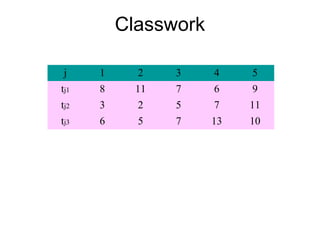

The document discusses sequencing problems and various sequencing rules used to optimize outputs when assigning jobs to machines. It describes Johnson's rule for minimizing completion time when scheduling jobs on two workstations. Johnson's rule involves scheduling the job with the shortest processing time first at the workstation where it finishes earliest. It provides an example of applying Johnson's rule to schedule five motor repair jobs at the Morris Machine Company across two workstations. Finally, it discusses Johnson's three machine rule for sequencing jobs across three machines.