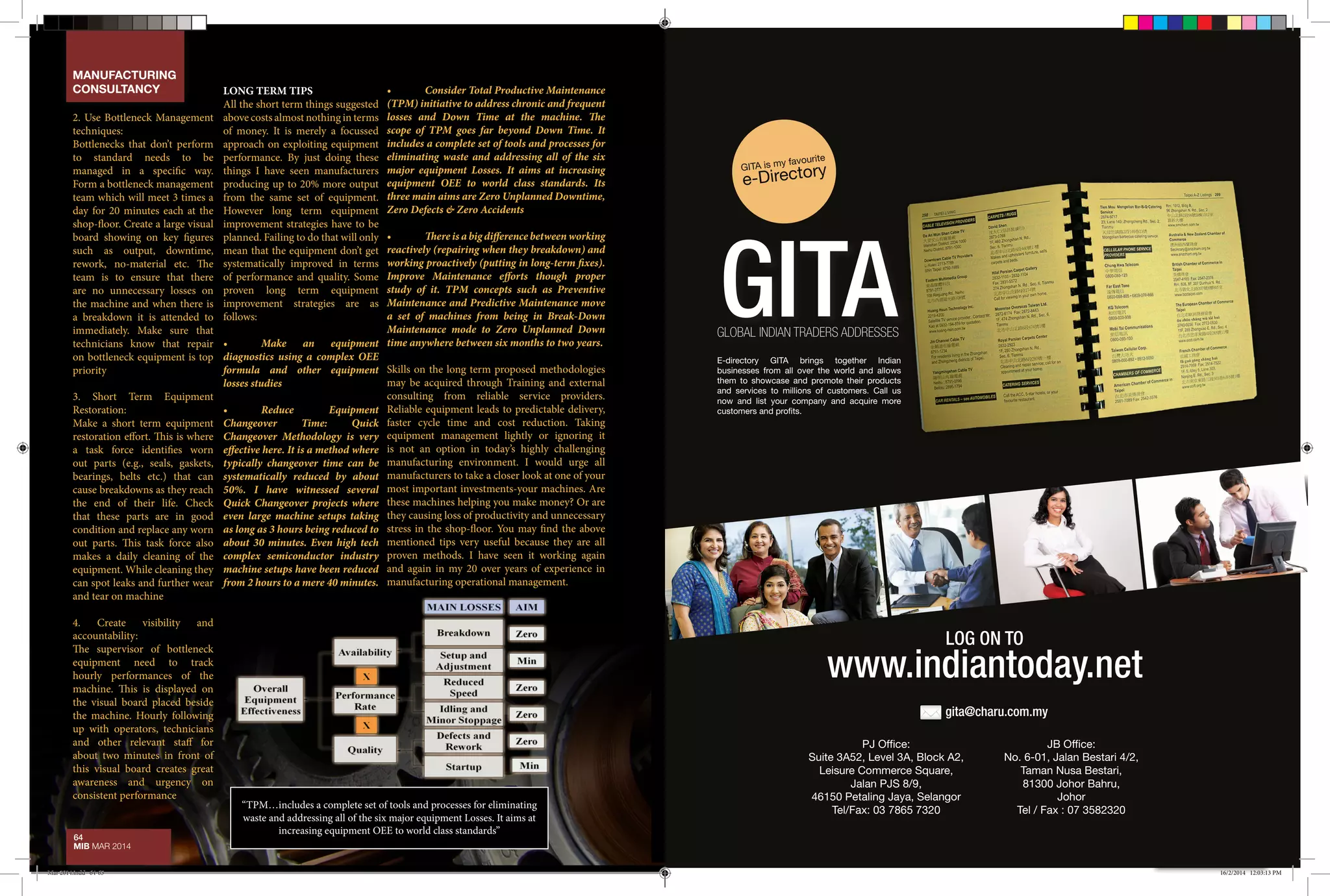

Equipment downtime is a major cause of productivity loss for manufacturers. Poorly maintained equipment leads to reduced output, lost revenue from missing production targets, and high inventory levels. It also causes confusion on the shop floor. Most manufacturers, especially small ones, rely on a breakdown maintenance approach rather than proactively maintaining equipment. This puts them at risk of losing control over their equipment performance. The document provides tips for both short-term and long-term improvement of equipment management, including measuring overall equipment effectiveness (OEE), addressing bottlenecks, preventative maintenance, and total productive maintenance (TPM) initiatives.