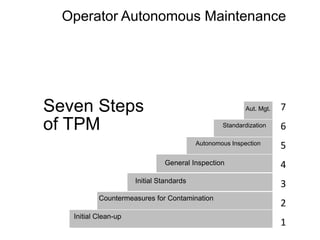

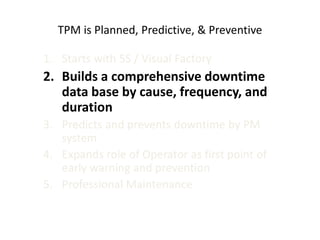

Total Productive Maintenance (TPM) was introduced by Japanese companies to improve equipment effectiveness and reduce costs and waste. It involves all employees in detecting and addressing equipment issues through concepts like autonomous maintenance performed by operators. The goals of TPM are to increase production while improving morale by minimizing downtime, defects, and other inefficiencies. Key aspects of TPM include the "five pillars" of focused improvement, autonomous maintenance, planned maintenance, quality maintenance, and education and training.