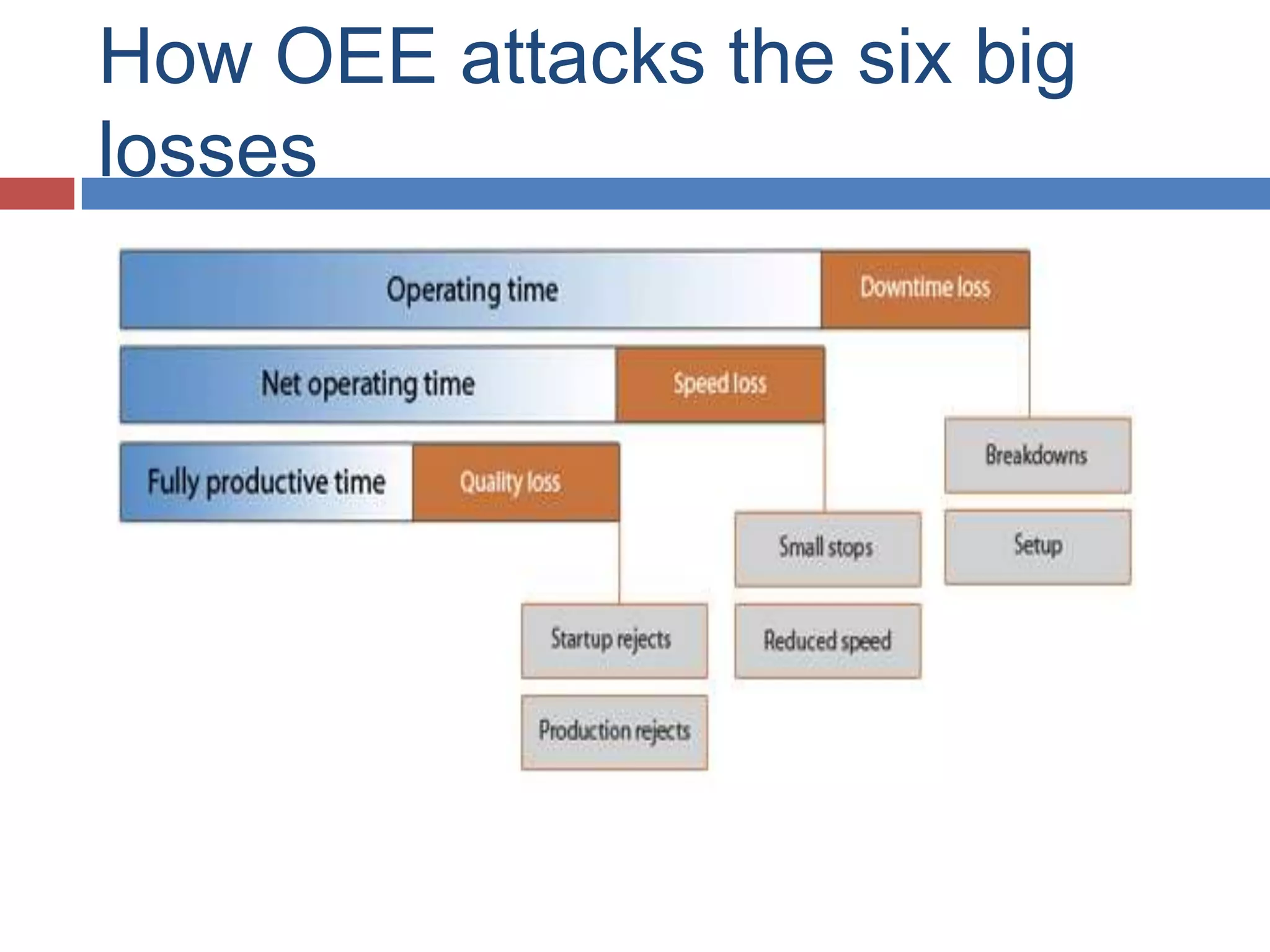

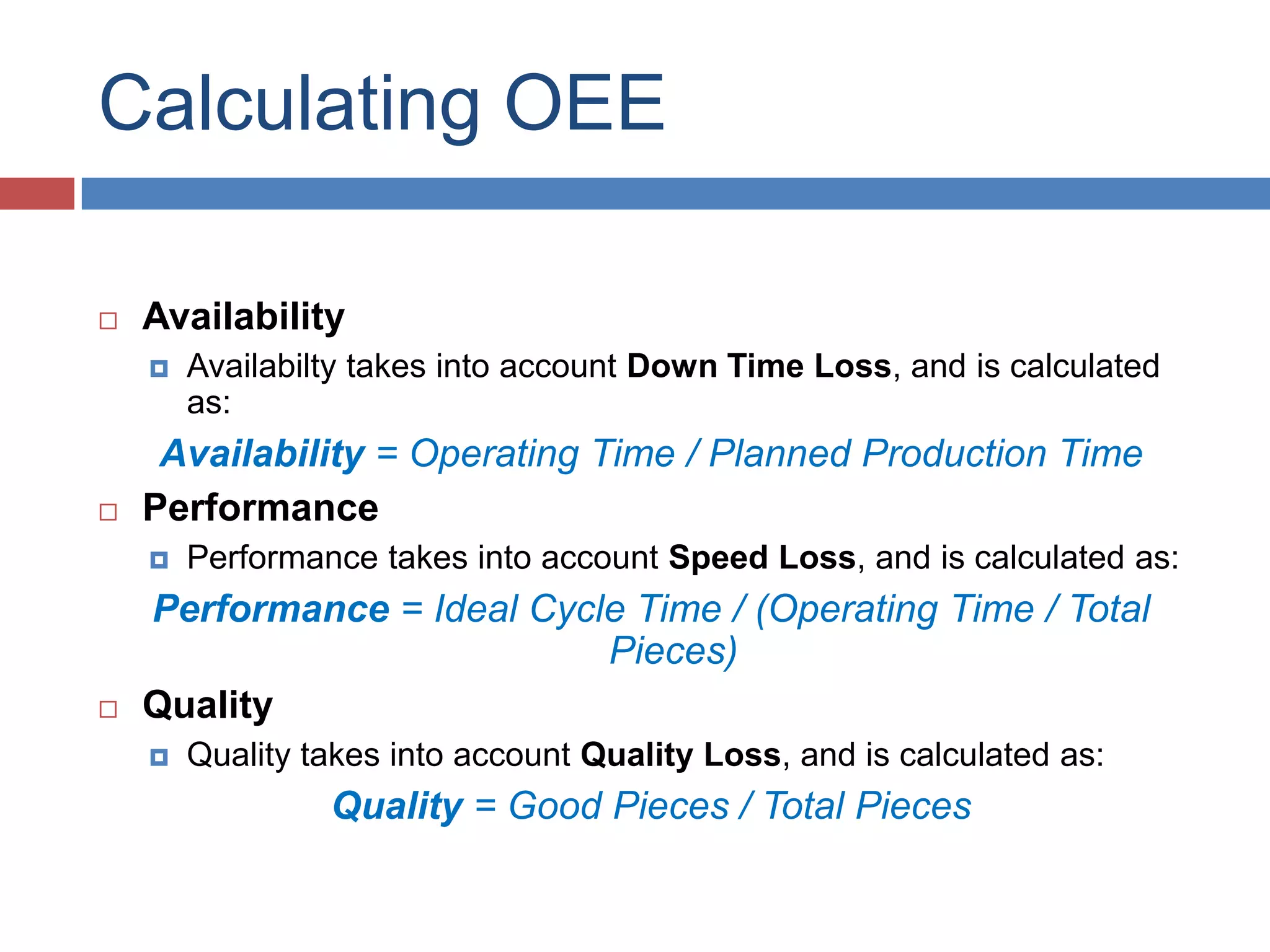

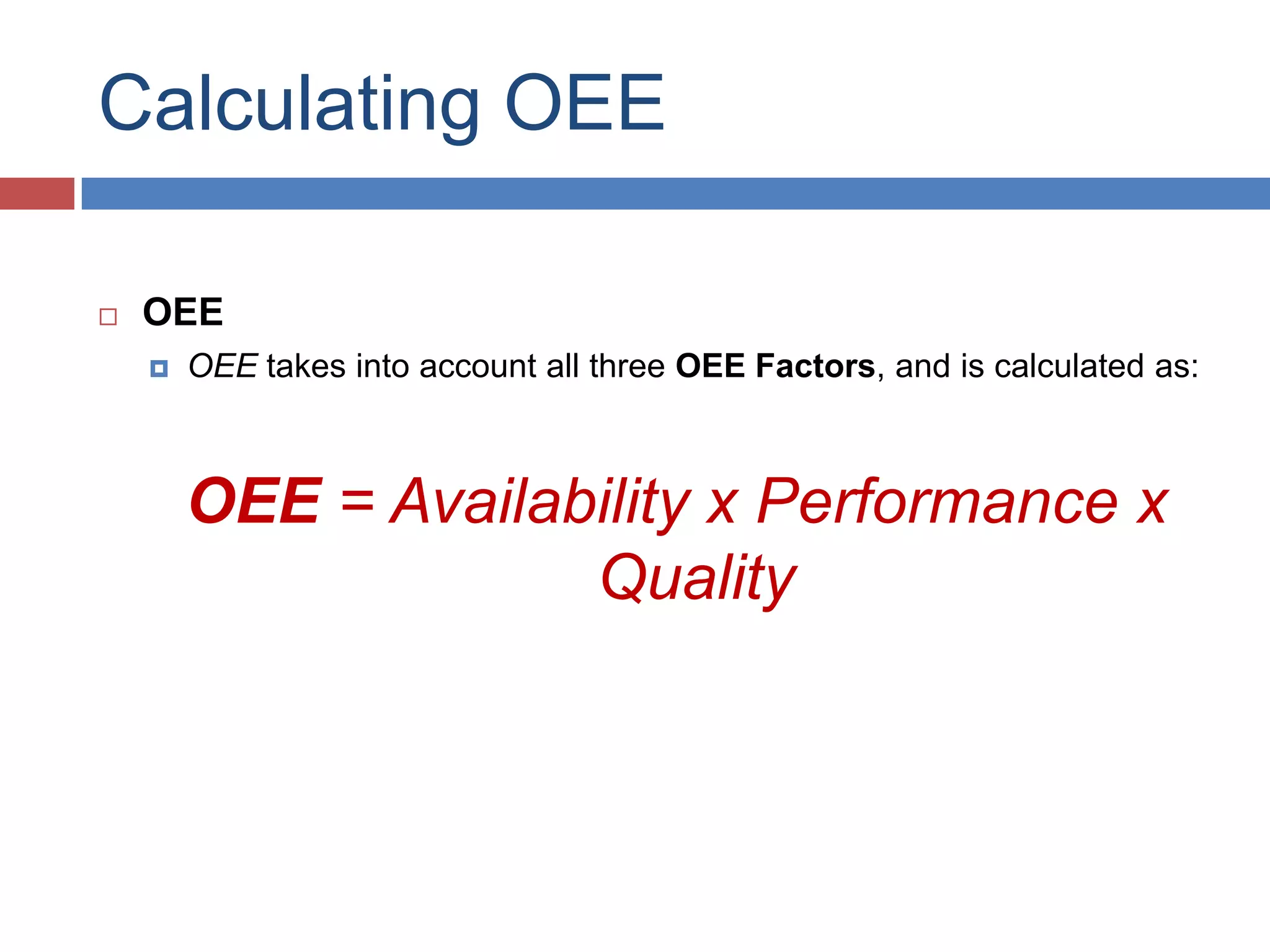

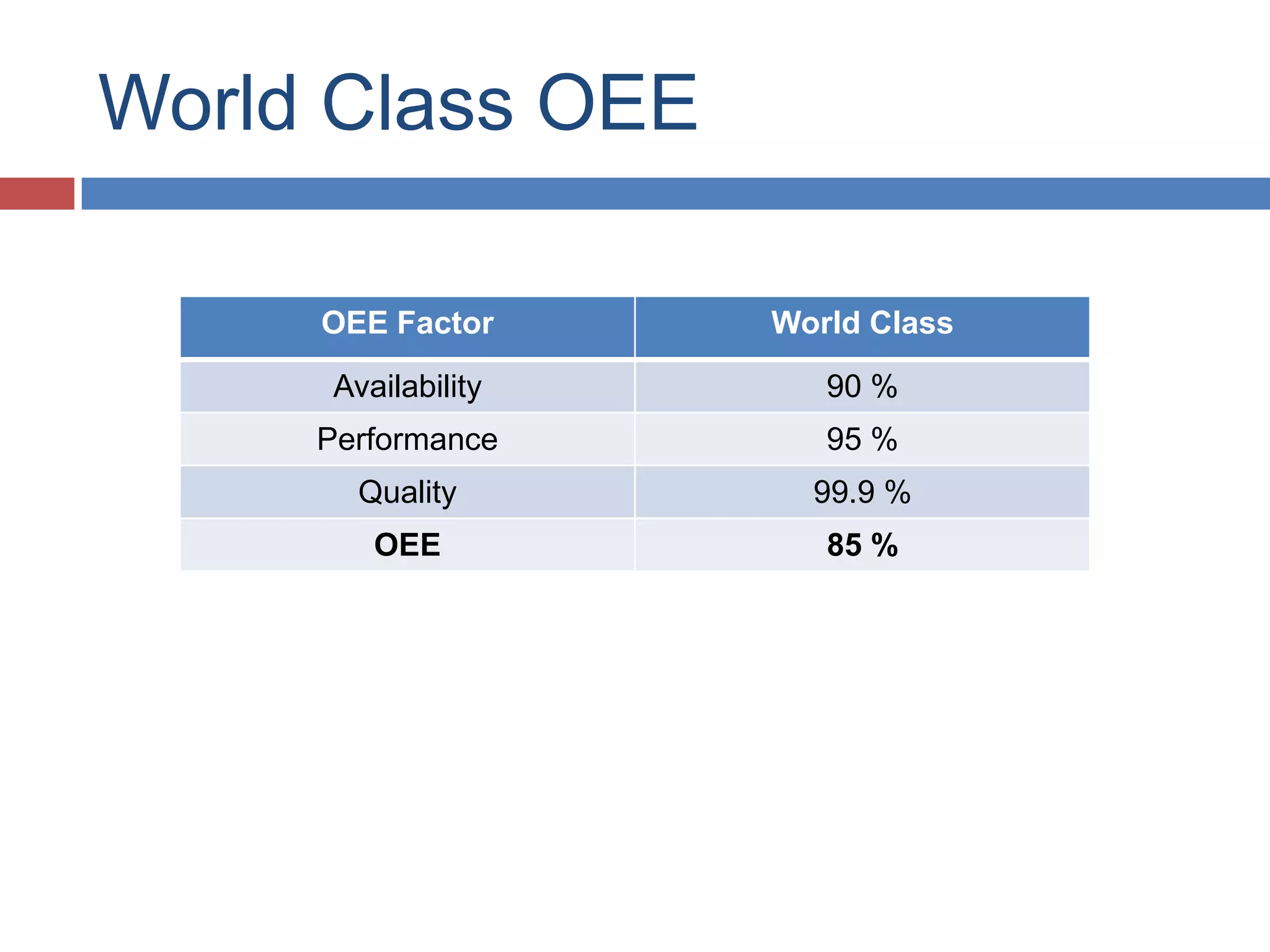

Overall Equipment Effectiveness (OEE) is a measurement system used to understand process performance and effectiveness. OEE measures three key factors - availability, performance, and quality - to determine the percentage of planned production time that is truly productive. It accounts for the six big losses that reduce productivity: breakdowns, setups, minor stops, reduced speeds, start-up rejects, and production rejects. Calculating OEE involves determining the availability, performance, and quality percentages and multiplying them together. Tracking OEE is important for strategic planning, investment decisions, and ensuring suppliers deliver as promised. It provides answers about investment confidence and current plant performance.