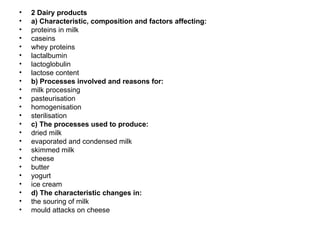

1) Milk contains various proteins including caseins that coagulate when milk sours and whey proteins that remain in the whey. Milk also contains the sugar lactose.

2) Common processes used in milk production include pasteurization to kill bacteria without affecting nutrition, homogenization to reduce fat globule size, and sterilization using higher temperatures.

3) Many dairy products result from milk processing, including cheeses produced through coagulation, butter, yogurt, evaporated/condensed milks with varying water content, and dried milk powders.