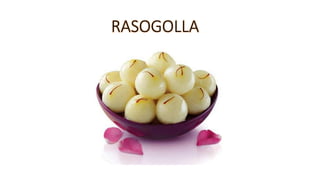

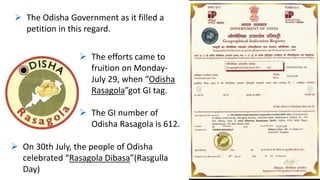

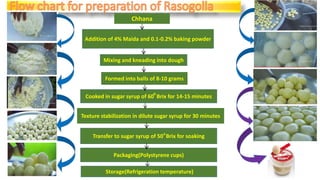

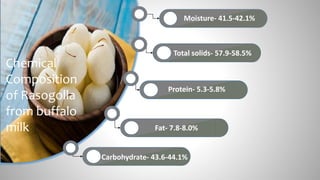

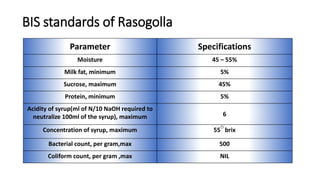

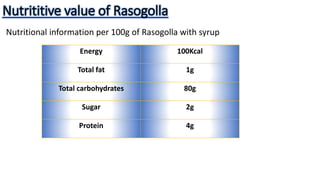

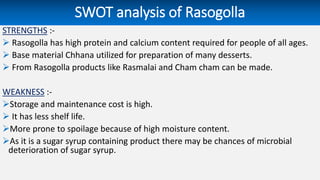

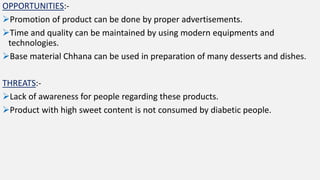

Rasgolla, a popular Bengal sweet developed by Nobin Chandra Das in 1868, has led to intense competition between West Bengal and Odisha regarding its origin, culminating in both states receiving geographical indication (GI) tags for their versions. The production of rasgolla is primarily handled by cottage and small-scale industries, with innovations leading to various forms and flavors. Nutritionally, rasgolla is a high-protein dessert that can aid in muscle building and bone health, but it has a short shelf life and high moisture content that makes it prone to spoilage.