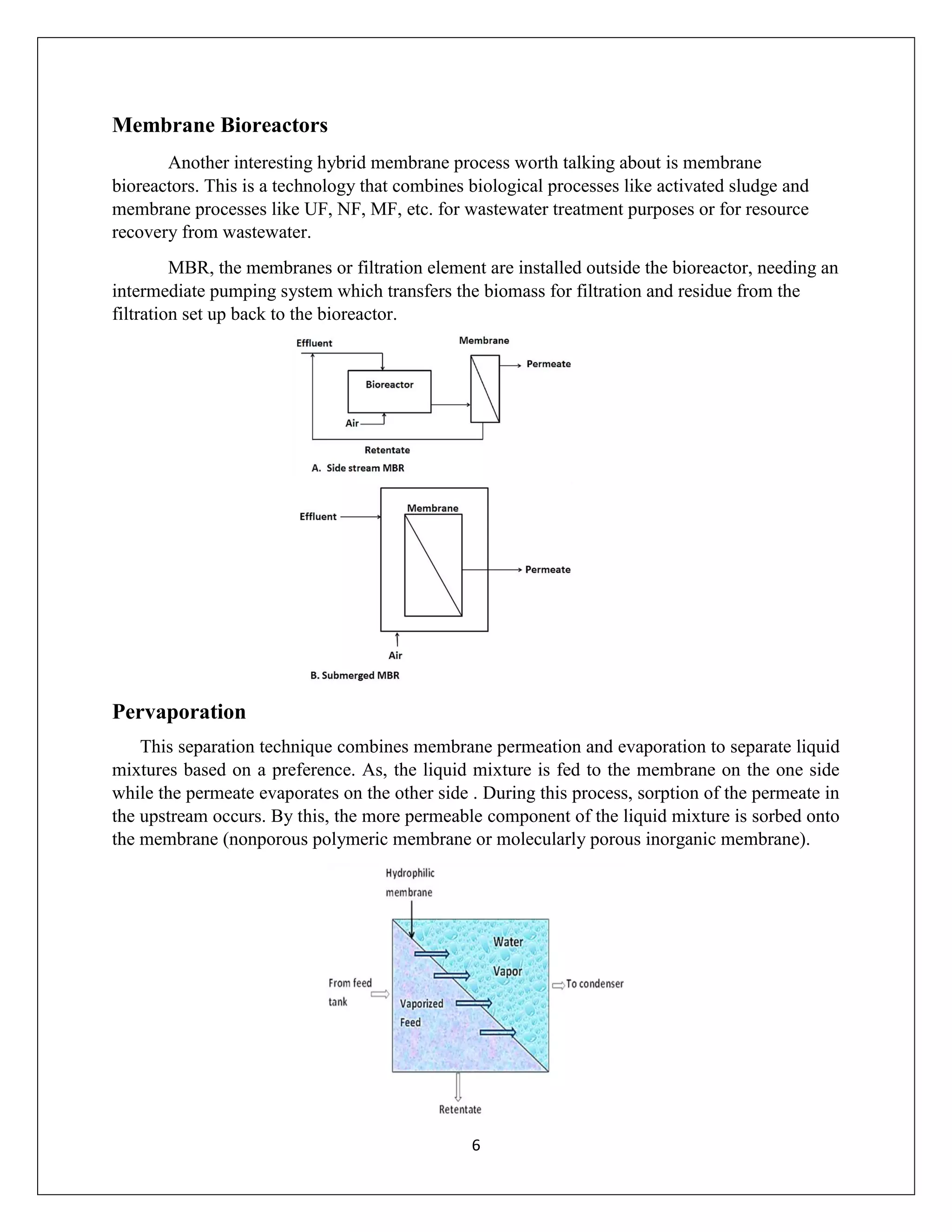

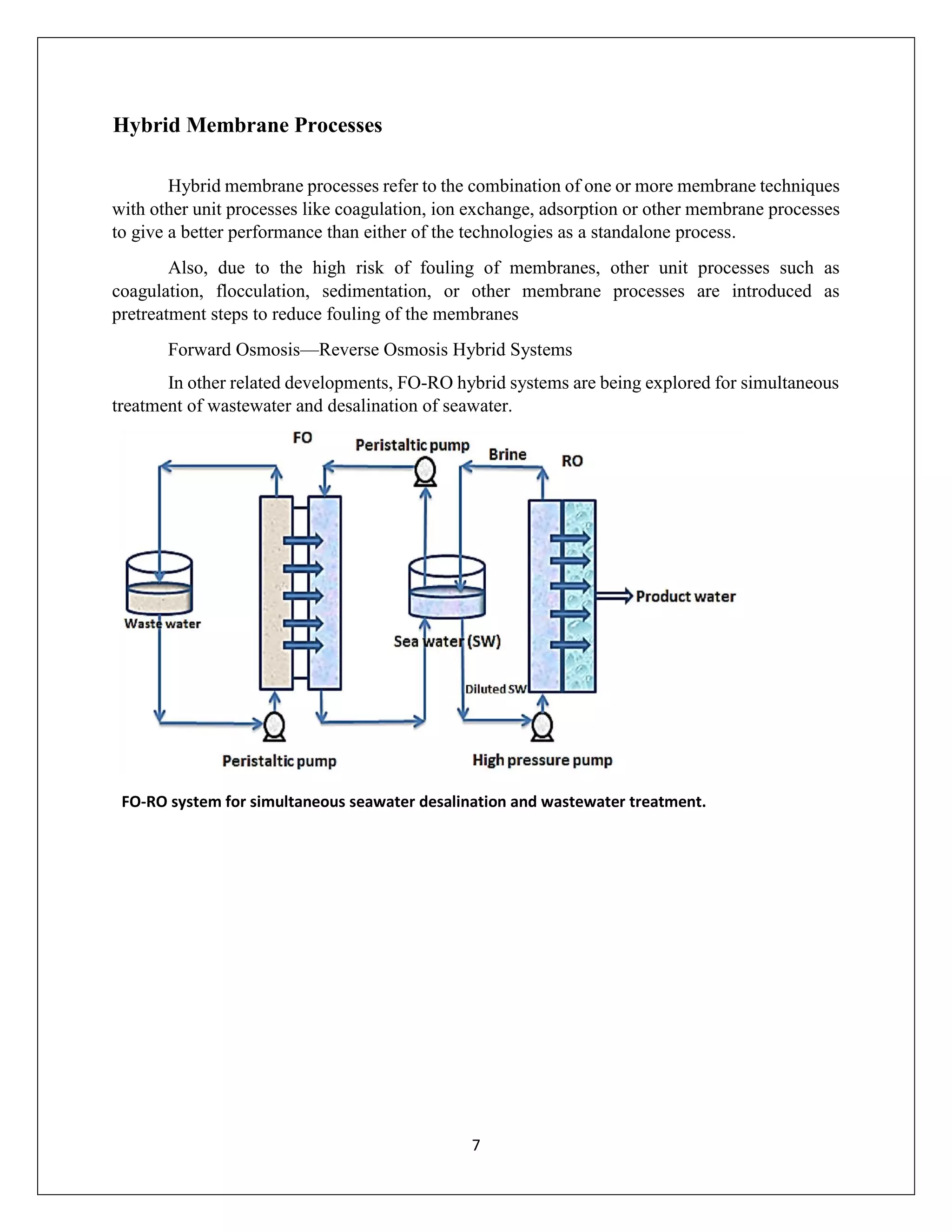

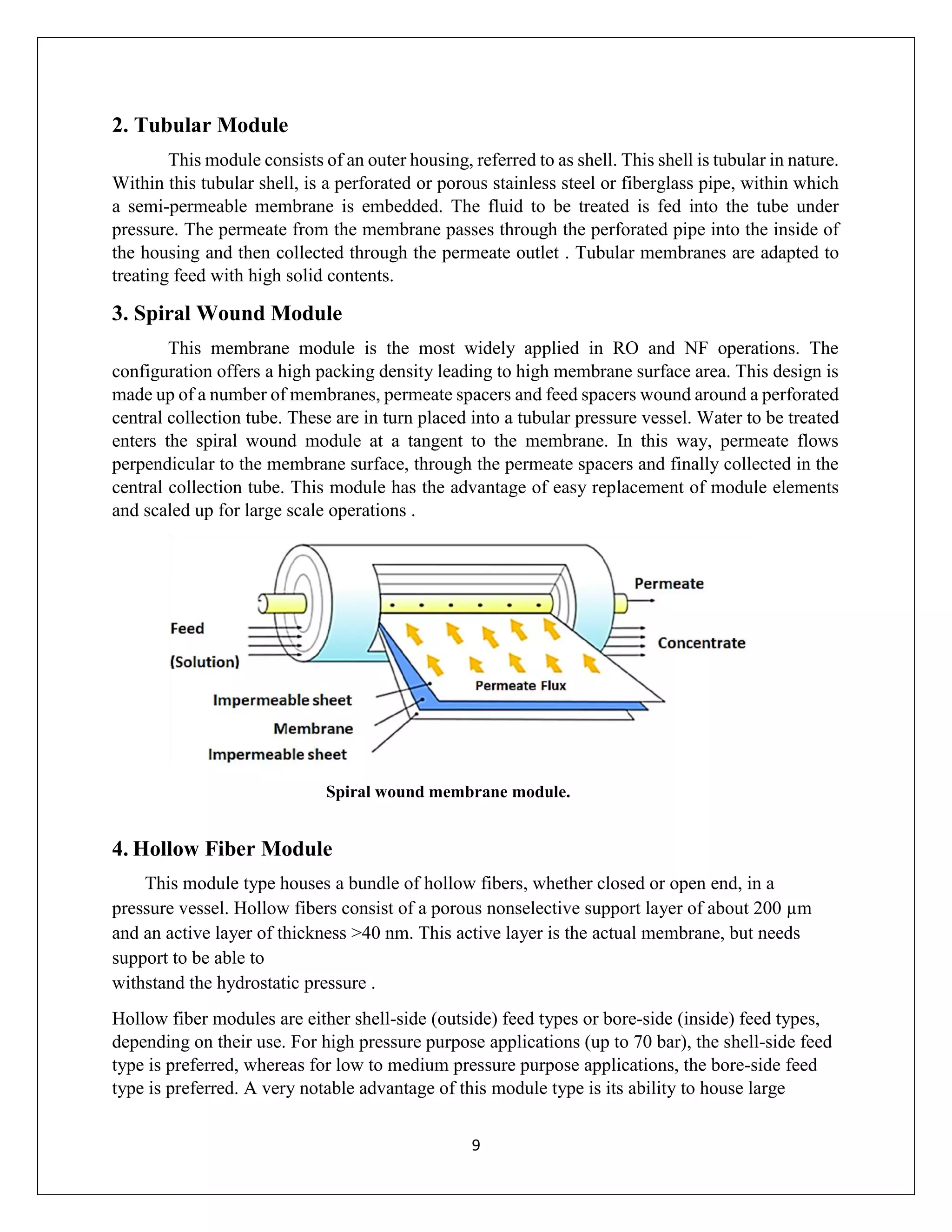

This document discusses membrane technologies used for wastewater treatment. It begins with an introduction to membranes and then discusses several membrane processes used for wastewater treatment including reverse osmosis, forward osmosis, electrodialysis, membrane bioreactors, and pervaporation. It also discusses hybrid membrane processes and membrane modules, focusing on plate and frame, tubular, spiral wound, and hollow fiber modules. Concentration polarization and membrane fouling are also covered along with pretreatment strategies to reduce fouling.