It contains:

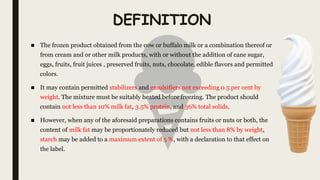

Definition of Ice Cream

Composition of Ice cream

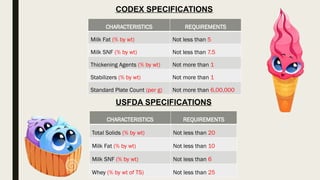

Specifications of Ice Cream - ISI, FSSAI, USFDA and CODEX Specifications

Types of Ice Cream - Plain Ice Cream, Chocolate Ice Cream, Fruit Ice Cream, Nut Ice Cream, Milk Ices or Lollies, Ices, Sherbets, Cassata, Mousse, Fancy Moulded Ice Cream, Novelties and Soft Ice Cream.

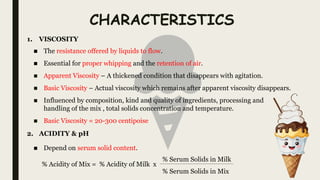

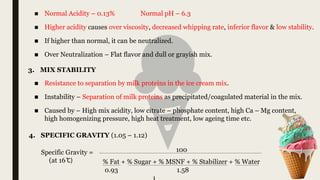

Characteristics of Ice Cream - Viscosity, Acidity, pH, Mix Stability, Specific Gravity, Surface Tension, Freezing Point and Whipping Rate

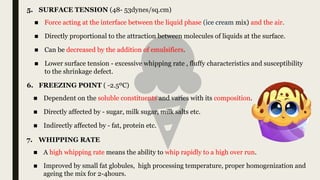

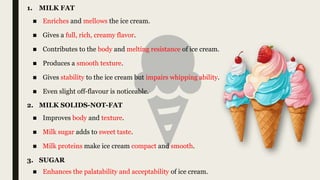

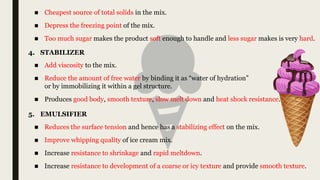

Ingredients in Ice Cream - Milk Fat, Milk SNF. Sugar, Stabilizer and Emulsifier.

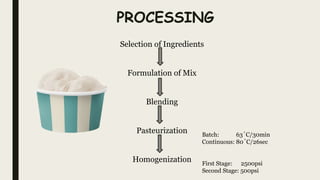

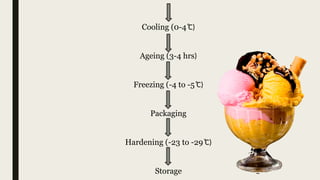

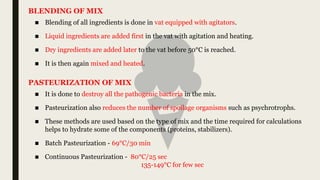

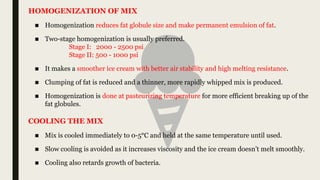

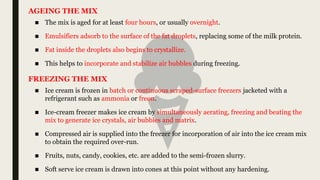

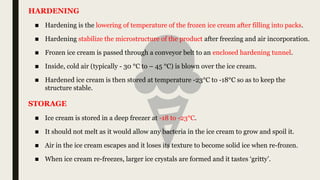

Ice Cream Processing Steps - Selection of Ingredients, Formulation of Mix. Blending, Pasteurization, Homogenization, Cooling, Ageing, Freezing, Packaging, Hardening and Storage.

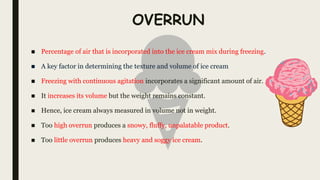

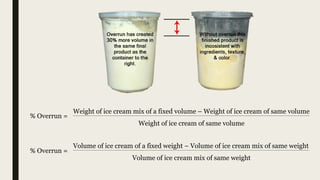

Overrun in Ice Cream