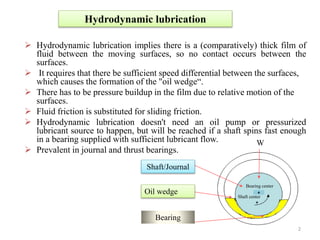

The document discusses hydrodynamic lubrication, which occurs when there is a thick film of fluid between moving surfaces so that contact does not occur. For hydrodynamic lubrication to happen, there needs to be sufficient speed difference between the surfaces to form an "oil wedge" and build up pressure in the fluid film from their relative motion. Reynolds' equation describes the relationship between pressure buildup, sliding speed, viscosity, and geometry of the hydrodynamic film. The document presents diagrams showing the velocity and pressure distributions in an inclined pad bearing under hydrodynamic lubrication conditions.

![Neglecting any side flow , the area of an element of film is 1×dy per unit width of the film. The

quantity flowing per unit time is thus u dy for each element area and the total flow q is given by

q= 𝟎

𝒉

𝒖 𝒅𝒚

Substituting for u from equation (7.3) and integrating

𝑞 = 0

ℎ

𝑈.

ℎ−𝑦

ℎ

𝑑𝑦 + 0

ℎ 1

2𝜂

−𝑑𝑝

𝑑𝑥

𝑦ℎ −

1

2𝜂

−𝑑𝑝

𝑑𝑥

𝑦2 𝑑𝑦

𝒒=

𝑼𝒉

𝟐

+

𝒉𝟑

𝟏𝟐𝜼

−𝒅𝒑

𝒅𝒙

.

7.4

At some point the pressure is maximum and

𝒅𝒑

𝒅𝒙

=0; let the value of h at this point be hm

(maximum) whence, 𝑞=

𝑈ℎ

2

+

ℎ3

12𝜂

−𝑑𝑝

𝑑𝑥

=0 [As some point the pressure is maximum;

𝒅𝒑

𝒅𝒙

=0]

𝑞=h(

𝑈

2

) [note: let the value of h at this point be hm]

qm=hm(

𝑼

𝟐

)

.

7.5

.

6

.

So,](https://image.slidesharecdn.com/hydrodynamiclubrication-160513065158/85/Hydrodynamic-lubrication-By-Khairul-Bashar-6-320.jpg)