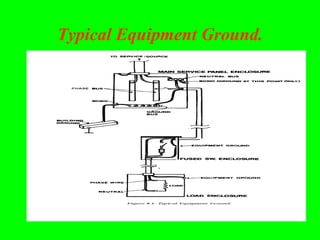

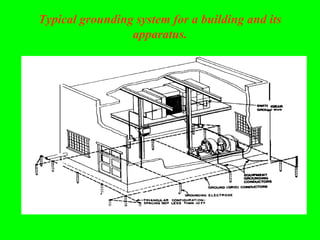

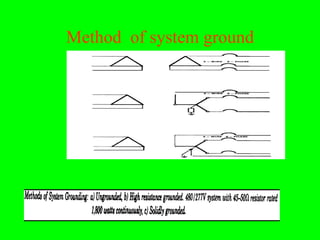

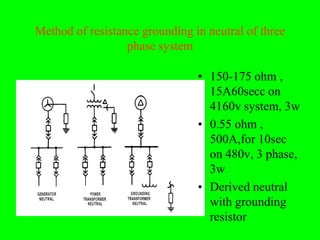

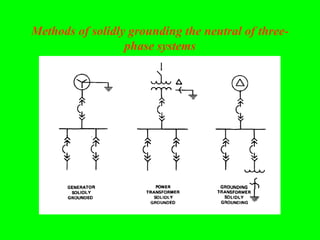

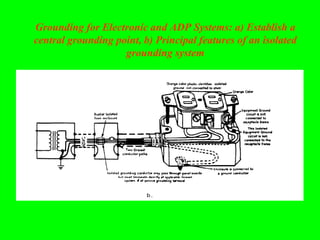

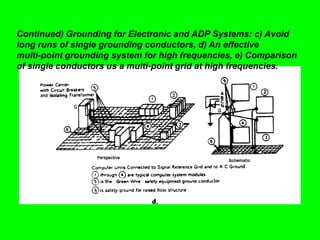

The document discusses different types of grounding systems used in high voltage systems, including: equipment grounds which connect metal parts to earth to protect from electric shock; system grounds which connect one point of an electrical circuit to earth to protect equipment and aid fault detection; and solidly grounded systems where the neutral is directly connected to ground without impedance. It notes factors like voltage level, equipment type, and safety that influence grounding method selection.