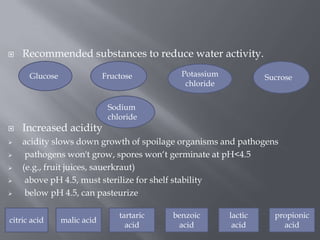

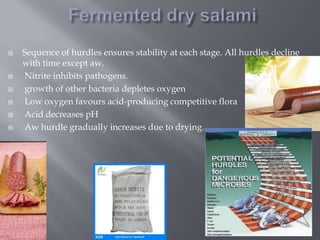

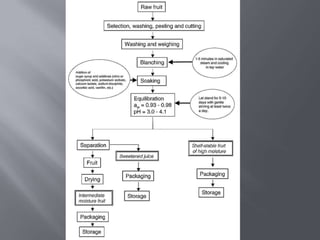

Hurdle technology combines multiple preservation methods to enhance food safety, quality, and shelf stability, responding to consumer demand for fresh and minimally processed products. The approach includes techniques such as pasteurization, sterilization, blanching, refrigeration, freezing, and reducing water activity to inhibit microbial growth. Overall, it aims to ensure food remains stable and safe while maintaining its sensory and nutritive value.