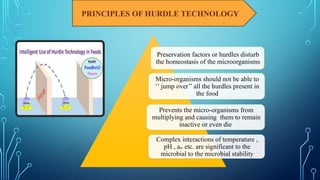

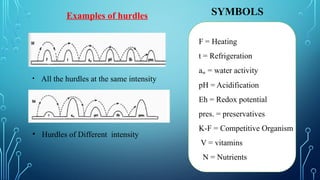

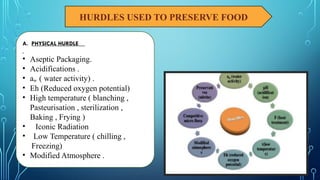

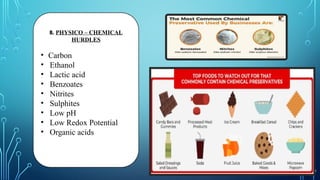

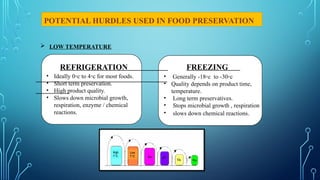

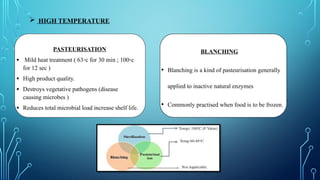

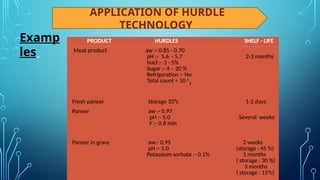

Hurdle technology combines multiple preservation methods to ensure food safety and stability while minimizing nutrient loss. It addresses consumer demands for fresh, minimally processed foods and employs various hurdles like physical and physico-chemical factors to inhibit microbial growth. This approach proves more effective and valuable compared to traditional methods, maintaining sensory and nutritional quality.