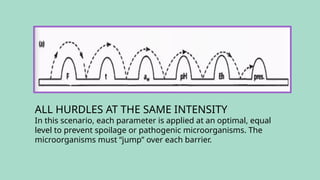

Hurdle technology is a food preservation method that combines multiple techniques to inhibit microbial growth and enhance food safety and shelf life. This approach disrupts microbial homeostasis, leading to metabolic exhaustion and auto sterilization, while also engaging different preservation factors like temperature and acidity to target various microbial vulnerabilities. Practical applications demonstrate its effectiveness across different food products, although challenges include ensuring optimal hurdle combinations and addressing potential impacts on sensory quality.