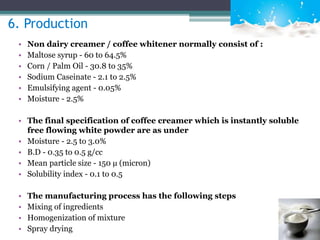

This document provides information on dairy whitener/non-dairy creamer, including its composition, production process, and common brands. It is made by mixing ingredients like corn syrup, palm oil, emulsifiers, and sodium caseinate. These mixtures are homogenized and then spray dried into a powder. Popular brands in India that produce dairy whitener include Nestle, Amul, and Britannia, which hold around 80% of the market share.