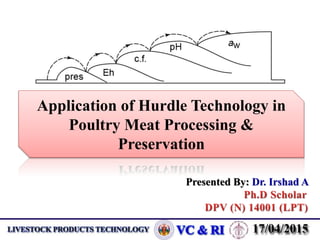

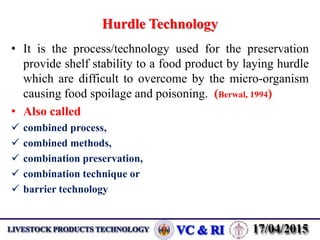

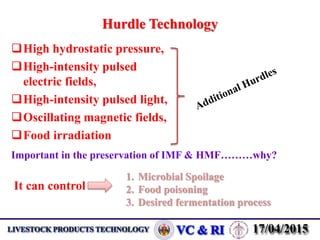

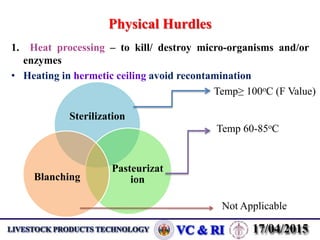

This document discusses hurdle technology, which uses a combination of preservation methods or barriers to inhibit microbial spoilage. It defines hurdles as physical, chemical, or microbiological factors that microorganisms must overcome to grow. Examples of hurdles include reduced water activity, acidity, heat treatment, packaging, and use of preservatives. The document provides examples of hurdles used in various products and outlines guidelines for developing shelf-stable foods using hurdle technology, including testing products with spoilage microorganisms and modifying hurdles as needed. Overall, it presents hurdle technology as an effective approach for food preservation and stability that can help reduce waste and extend product shelf life.