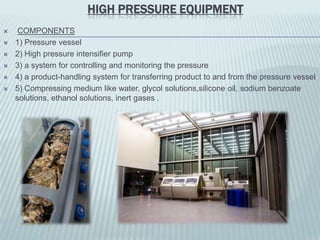

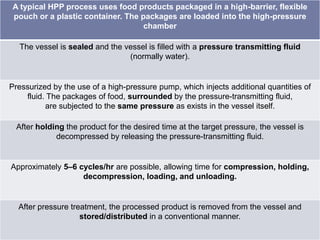

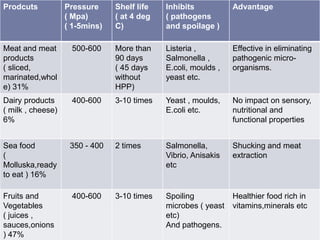

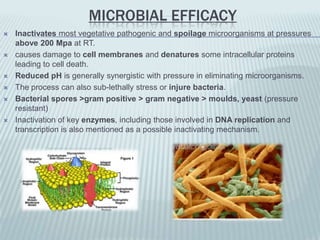

High-pressure processing uses high pressure, rather than heat, to preserve foods by inactivating harmful pathogens. Pressurizing foods to levels above 200 MPa uniformly inactivates microorganisms like bacteria and extends shelf life with little effect on taste, texture or nutrition. The process involves sealing foods in flexible packages and submerging them in water inside a high-pressure vessel. As pressure is applied, microorganisms are inactivated due to damage to cell membranes and proteins. This non-thermal method allows for minimal quality loss compared to heating and improves food safety.