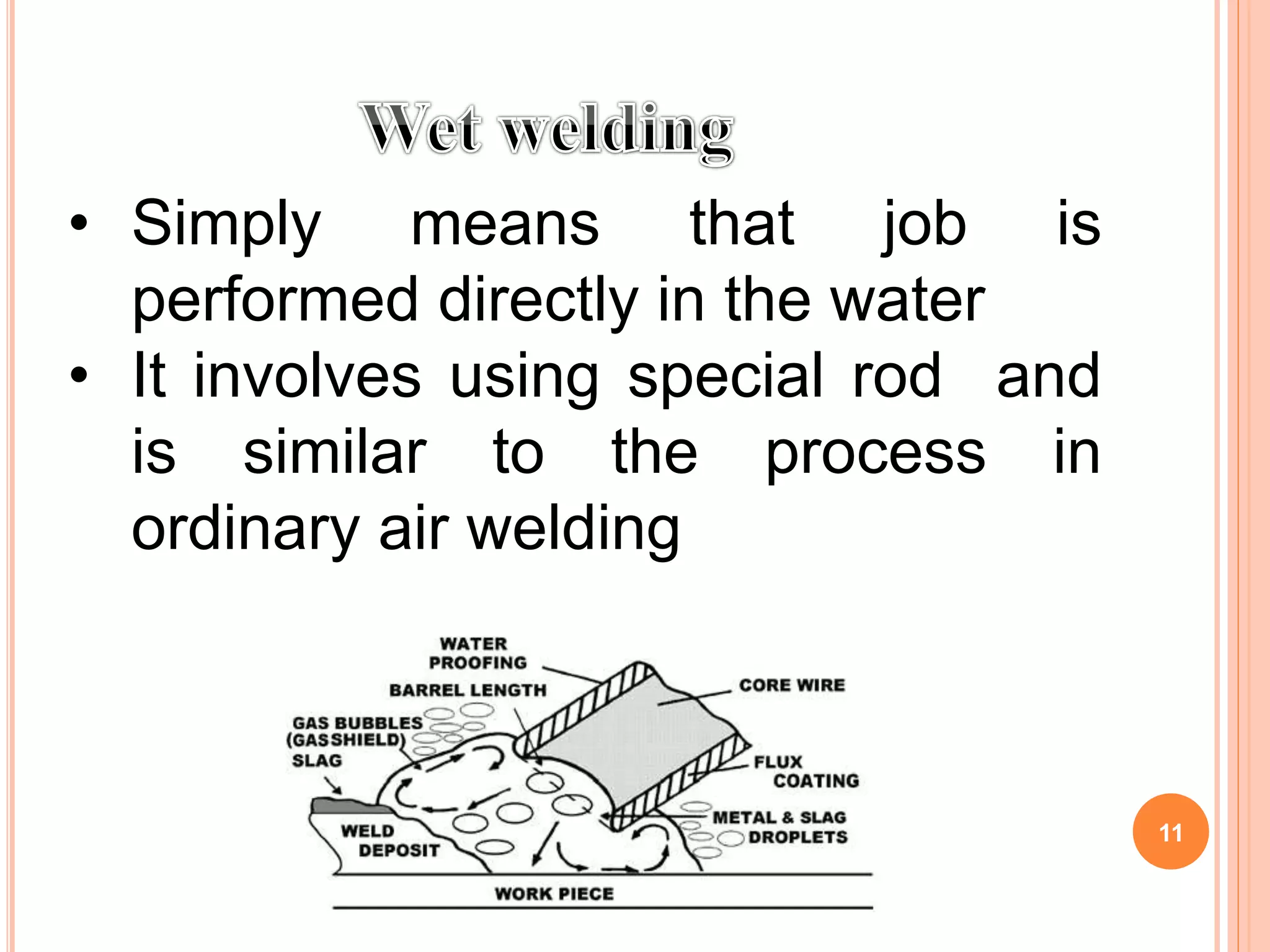

The document discusses the history and methods of underwater welding, including the development of waterproof electrodes and procedures established by the American Welding Society. It highlights the differences between wet and dry welding techniques, their applications, advantages, and associated risks. Additionally, it addresses advancements in welding technology, such as automated systems for improved efficiency and safety in underwater construction and repairs.