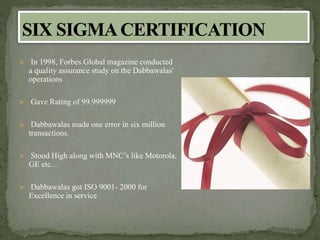

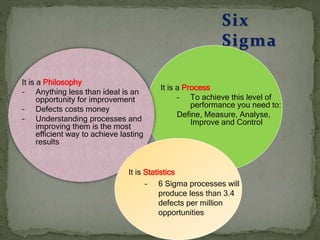

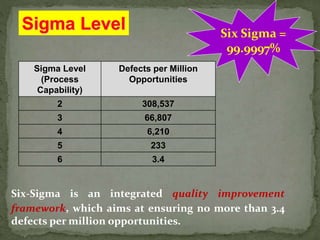

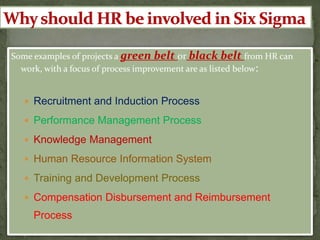

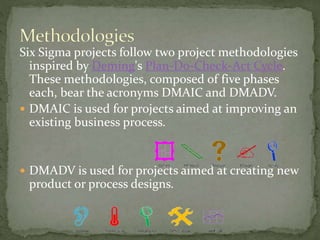

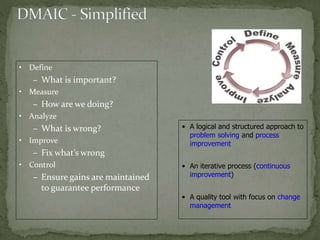

Six Sigma is a set of techniques and tools for process improvement. It aims to improve the quality of process outputs by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. The core idea is that if you have six standard deviations between the process mean and the nearest specification limit, you will produce 3.4 defective parts per million opportunities. Six Sigma follows the DMAIC model which stands for Define, Measure, Analyze, Improve, and Control. It relies on a strong emphasis on data and statistics to measure and improve processes. The Dabbawala system in Mumbai, India is often cited as an example of a near Six Sigma level process with an error rate of around 1 in 16 million deliver

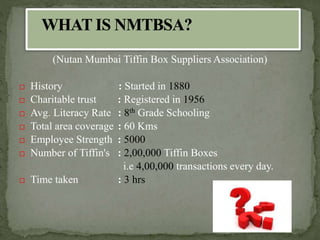

![Error Rate : 1 in 16 million transactions

•Six Sigma performance (99.999999)

•Technological Backup : Nil.

•Cost of service -Rs. 300/month ($ 6.00/month)

•Standard price for all (Weight, Distance, Space)

•Rs. 36 Cr. Turnover approx. [6000*12*5000=360000000 i.e

Rs. 36 crore p.a.]

•“No strike” record as each one a share holder •Earnings -5000

to 6000 p.m.

•Diwali bonus: one month’s from customers.](https://image.slidesharecdn.com/hrsixsigmasamarth-150429061044-conversion-gate01/85/Hr-six-sigma-25-320.jpg)