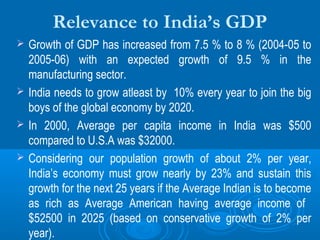

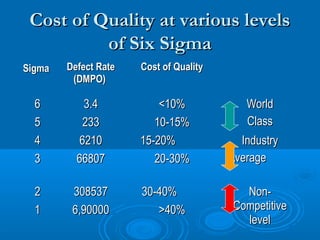

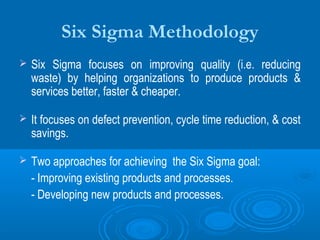

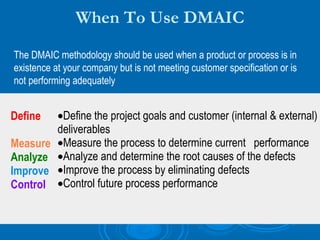

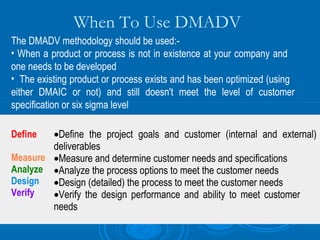

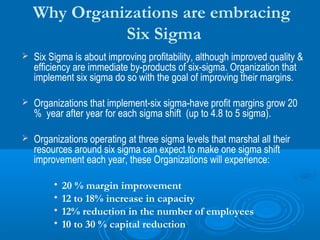

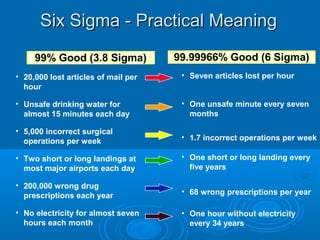

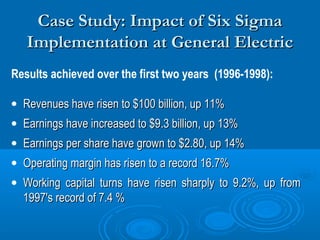

This document discusses the relevance of Six Sigma to India's economic development. It provides an overview of Six Sigma, including its history, definition, methodology, belts, and applications. Six Sigma was developed by Motorola to improve process quality and reduce defects. It aims for no more than 3.4 defects per million opportunities. Regular use of Six Sigma can help organizations achieve 20% annual profit margin growth through quality improvements, capacity increases, staff reductions, and capital savings. The document also outlines a case study of General Electric's improved financial results after implementing Six Sigma.