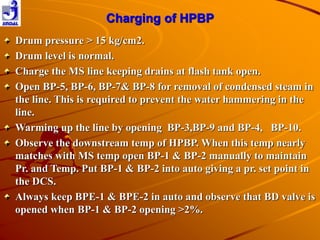

The document describes the HP bypass system for a steam turbine. The system comprises two HP bypass valves that direct main steam around the HP turbine to the reheater, and two LP bypass valves that direct steam from the reheater around the IP and LP turbines to the condenser. The bypass system is designed to pass 60% of rated steam flow. It is used for starts, transients, load rejection, and to avoid boiler trips by handling excess steam flow. It provides operational and economic benefits like faster starts, reduced thermal stresses, efficient reheating, and house load capability during grid disturbances. The document outlines checks, lineups, controls, protections, and operating conditions for the HP bypass valves.

![General

The Bypass System comprises

Two HP Bypass valve to take Main Steam

from before HPESV to Reheater inlet

bypassing the HP Turbine and

Two LP Bypass Valves that direct Steam from

Reheater outlet to Condenser bypassing the

IP & LP Turbines.

The HPLP Bypass system designed to pass

60% of the rated Turbine Steam flow [which

is 741 Te/hr].](https://image.slidesharecdn.com/hplpbp-211214141412/85/Hplpbp-2-320.jpg)