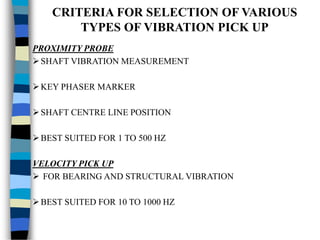

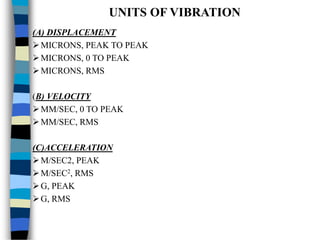

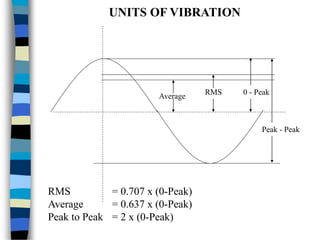

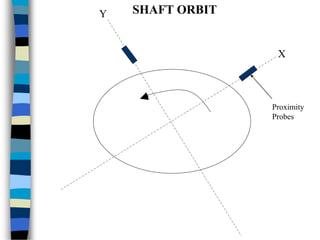

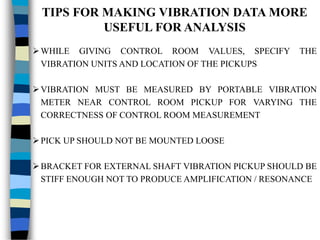

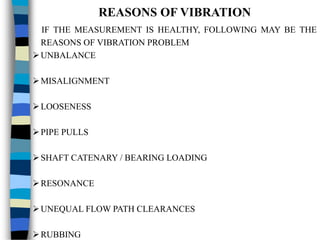

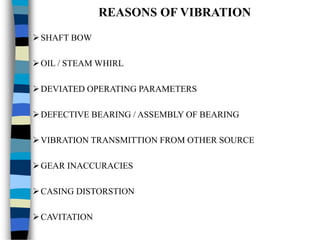

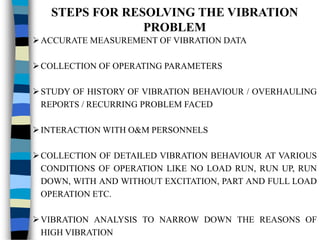

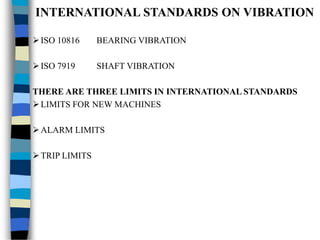

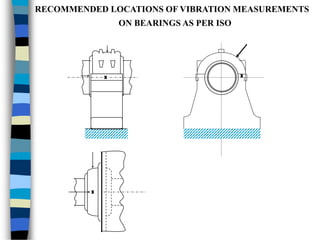

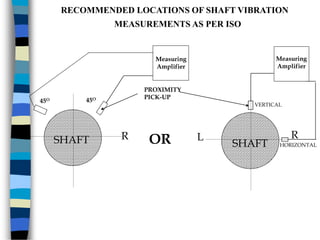

The document discusses basics of vibration including characteristics like amplitude, frequency, and phase. It describes common vibration pickups like proximity probes, velocity pickups, and accelerometers and criteria for selecting them. Methods of vibration measurement are presented along with units of vibration. Tips are provided for making vibration data useful and steps to resolve vibration problems are outlined. Standards for vibration limits on bearings and shafts are also mentioned.