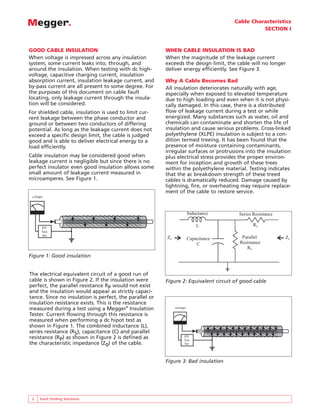

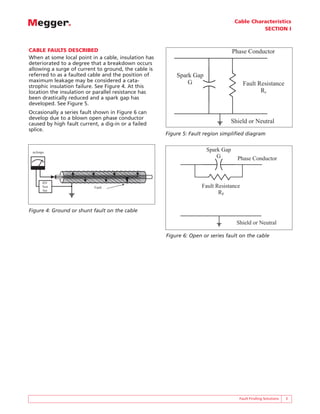

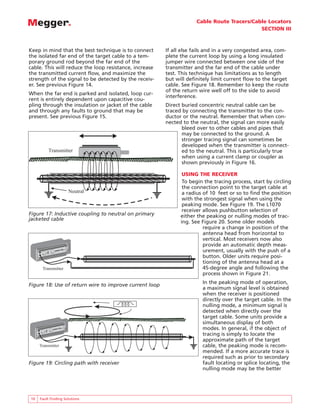

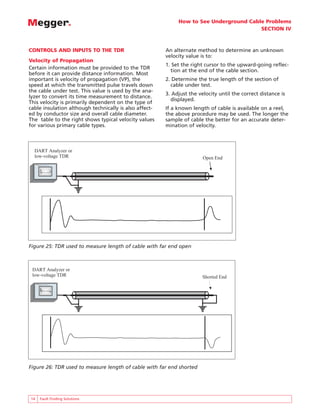

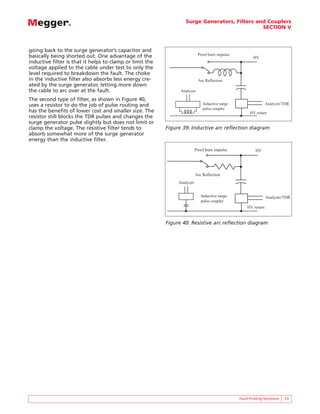

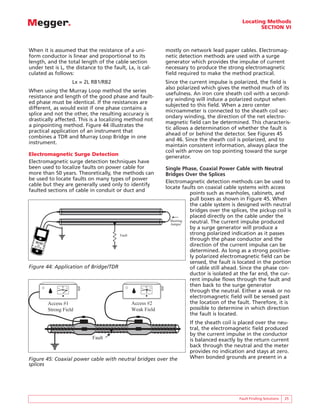

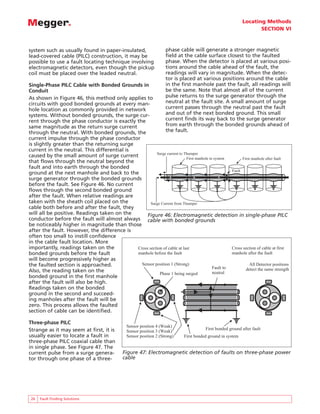

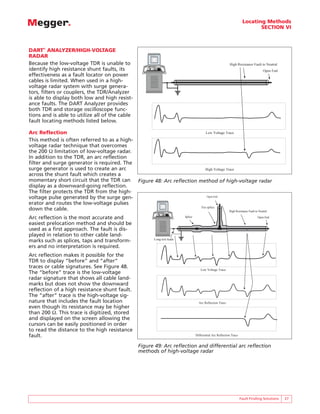

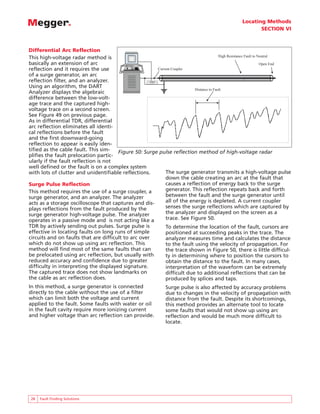

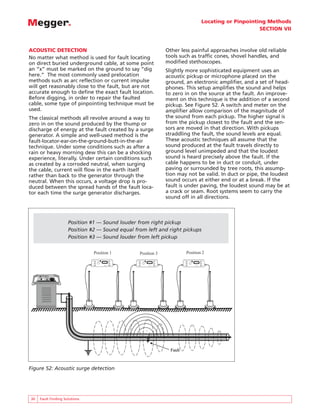

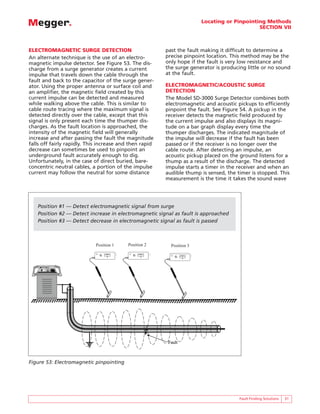

This document provides information on fault finding solutions for electrical cables. It discusses cable characteristics and different types of cable faults. It then describes procedures for locating faults in buried primary cables, which include cable testing methods like fault resistance tests, time domain reflectometry (TDR) tests, and DC hipot tests. It also discusses analyzing the test data and localizing or pinpointing the fault. Additional sections cover cable locators, low-voltage TDRs, surge generators, cable fault localizing methods, pinpointing techniques, and various fault locating equipment solutions.