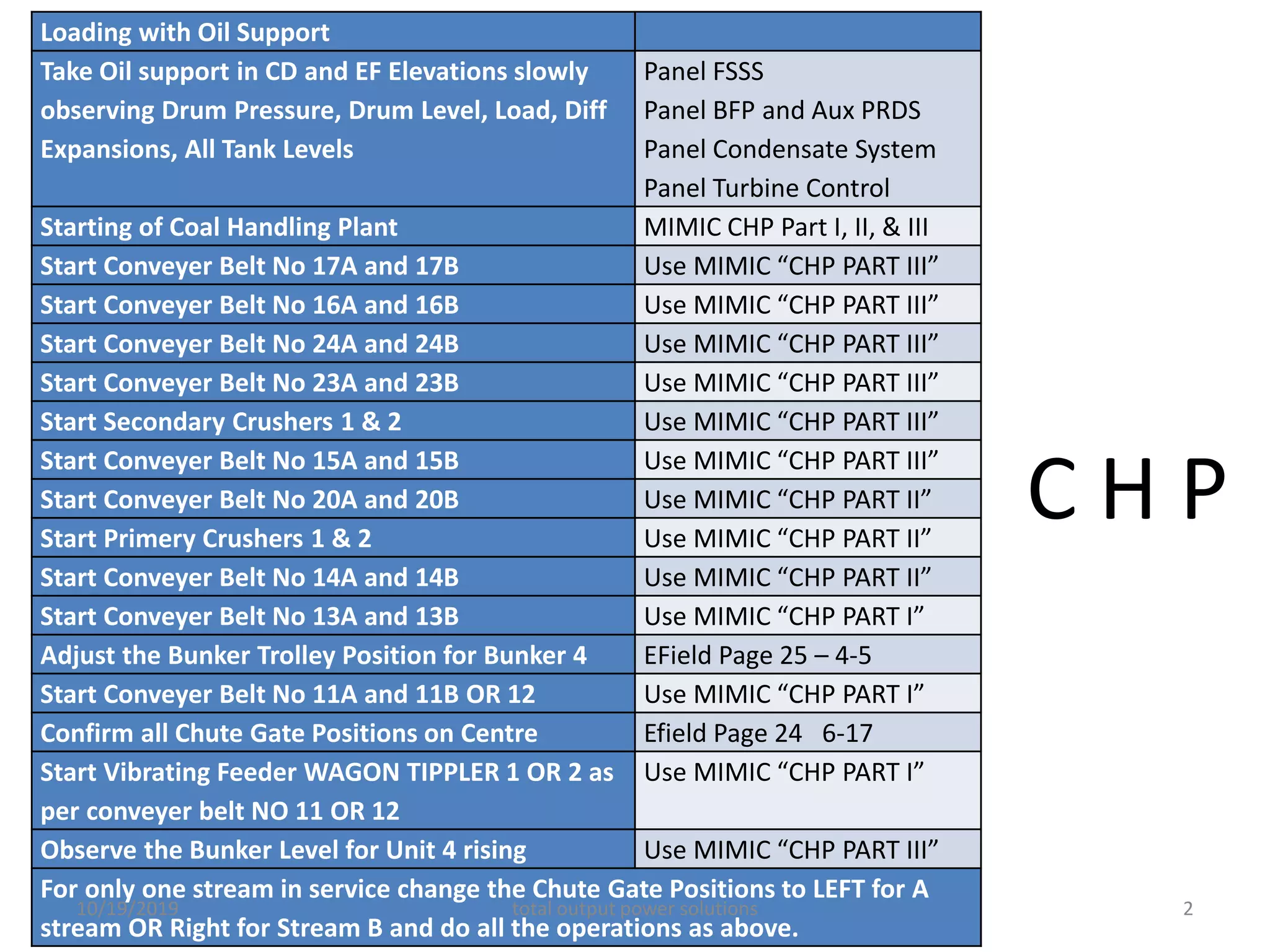

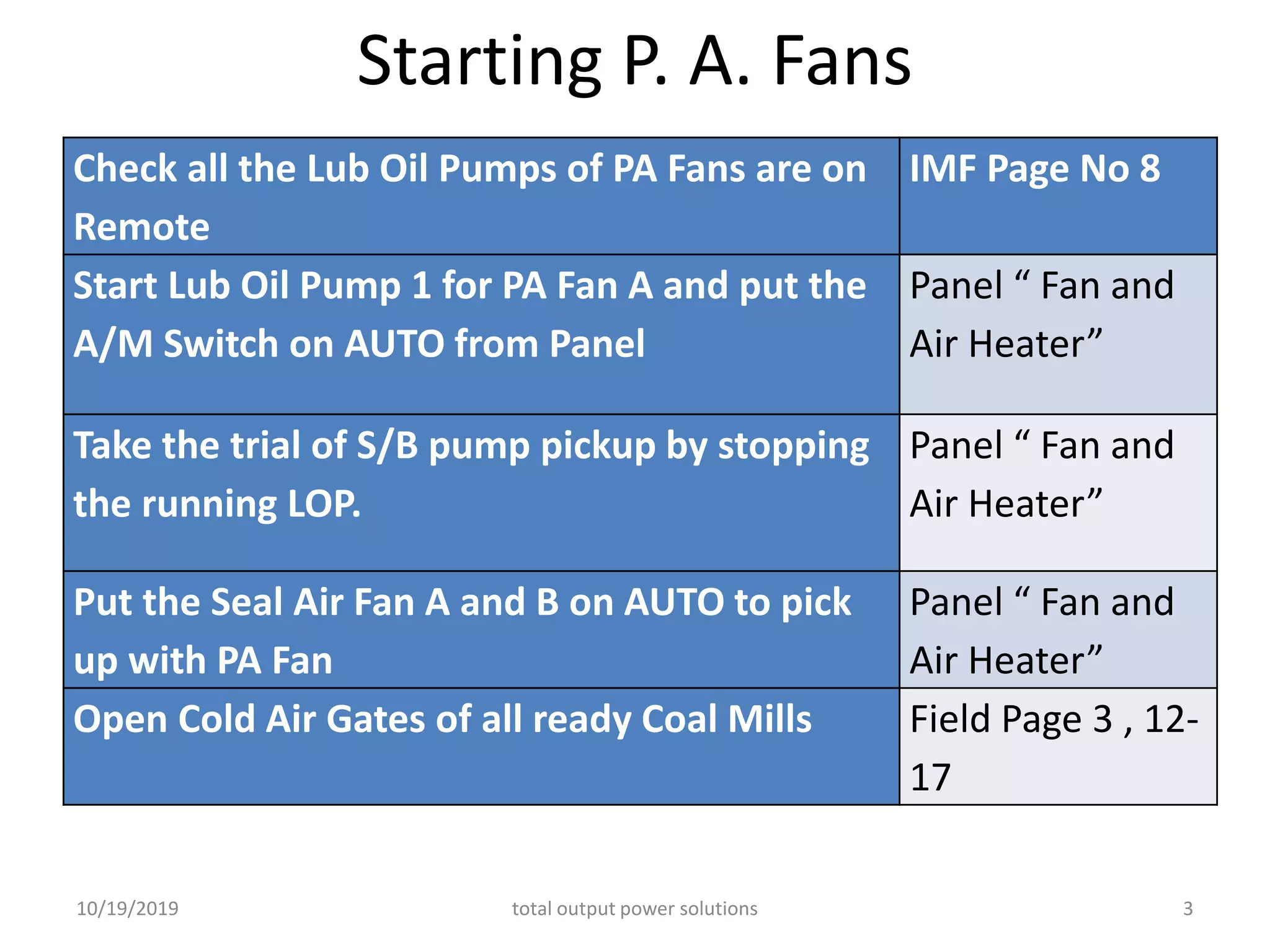

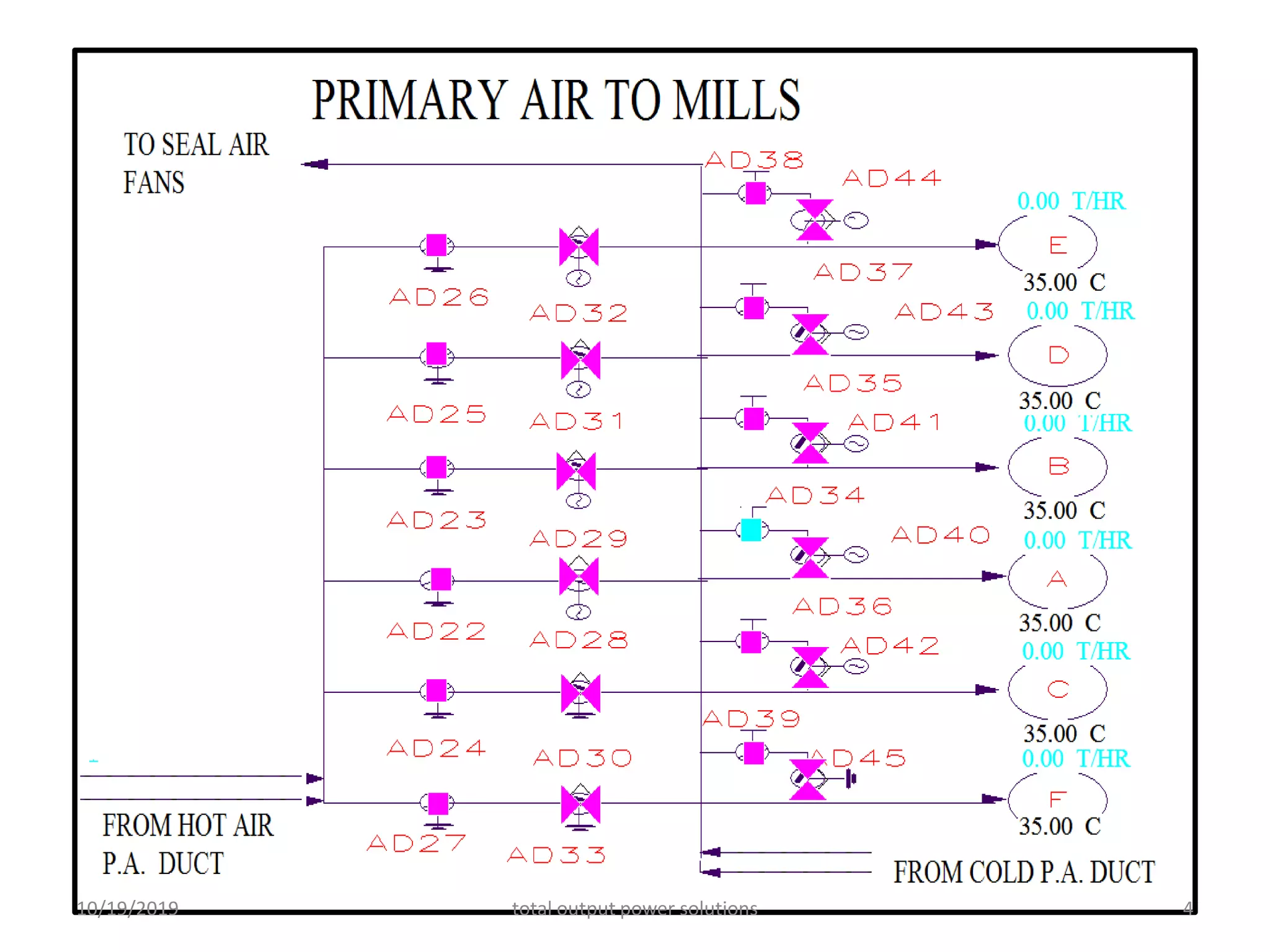

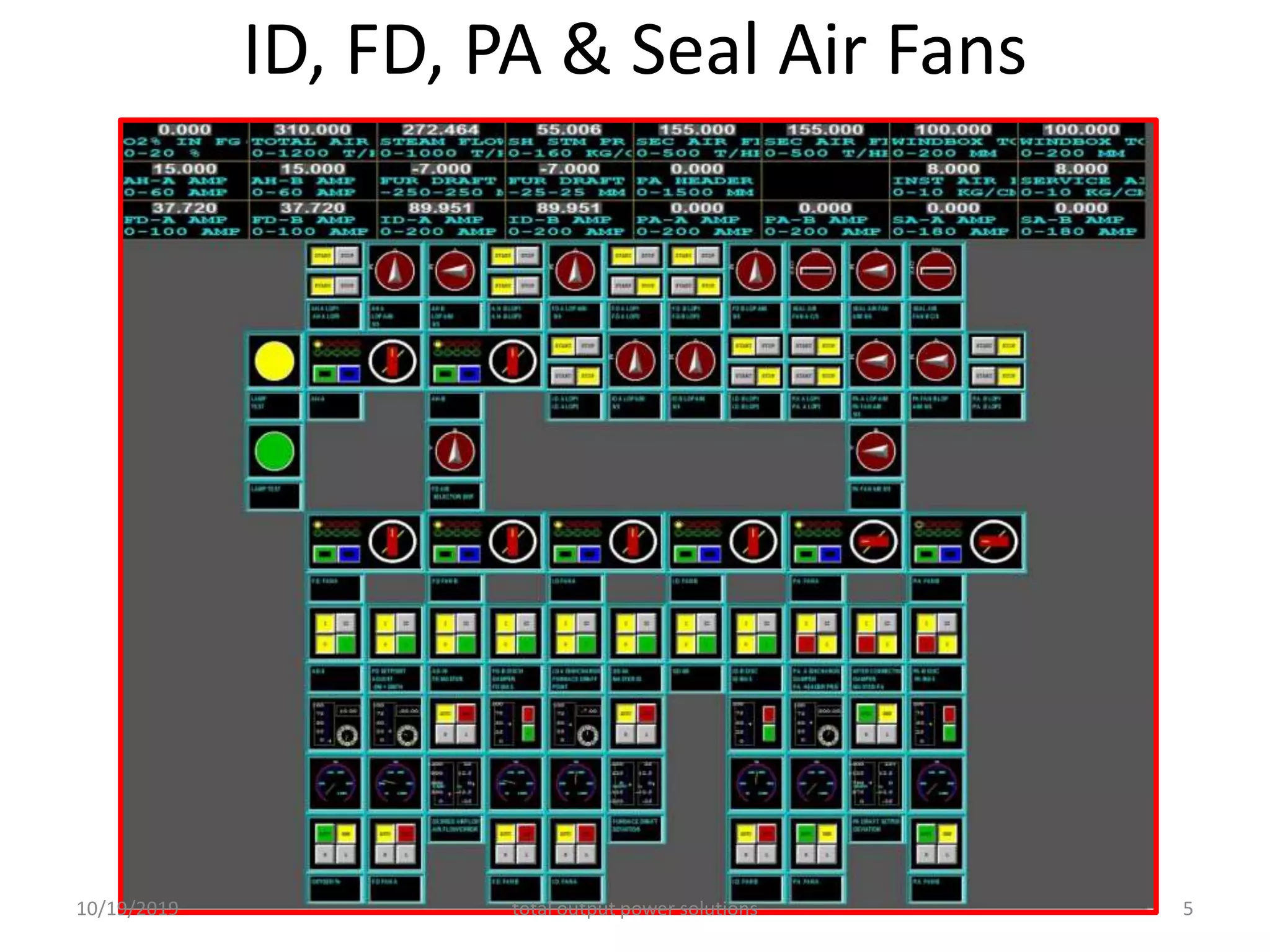

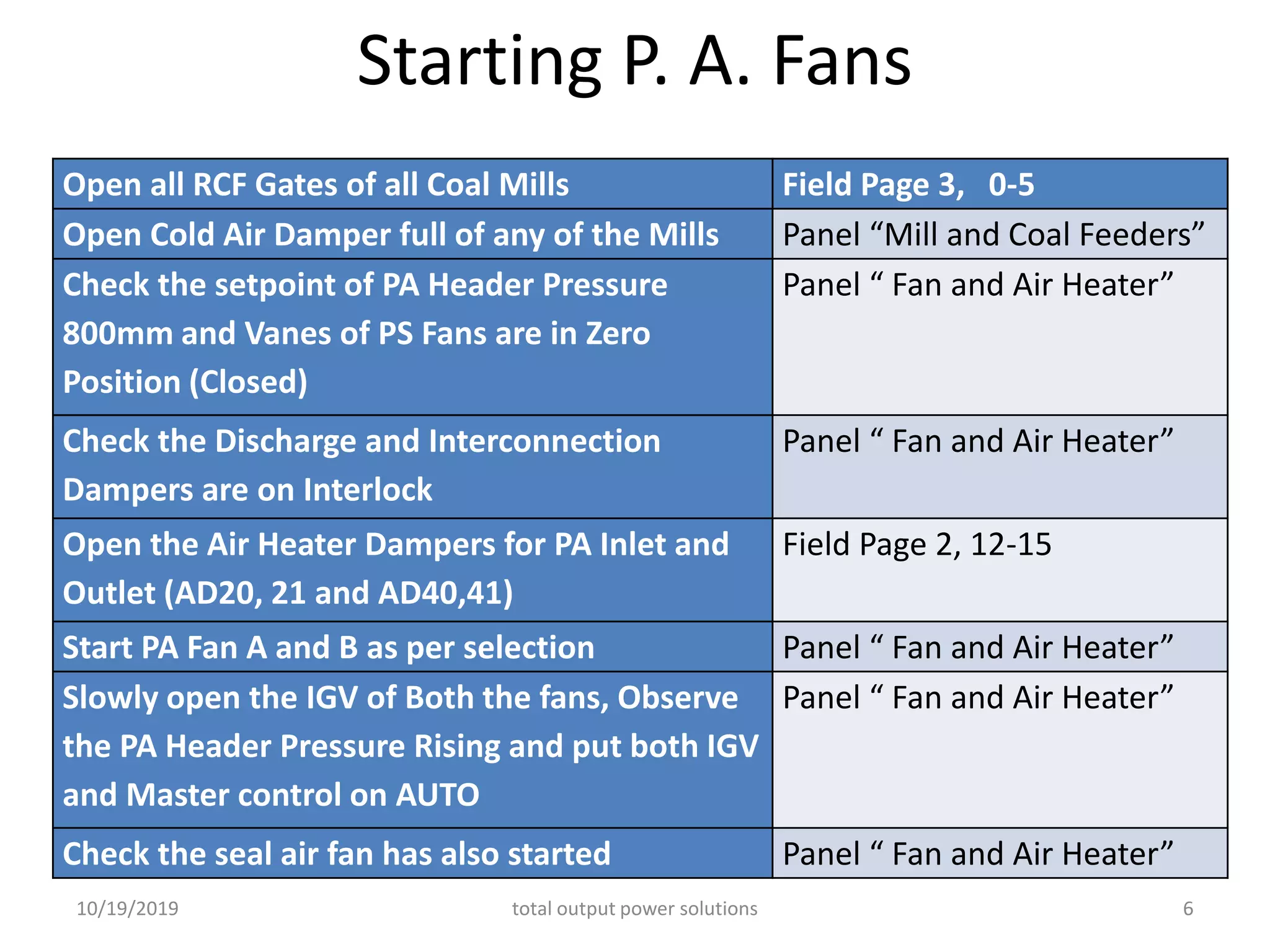

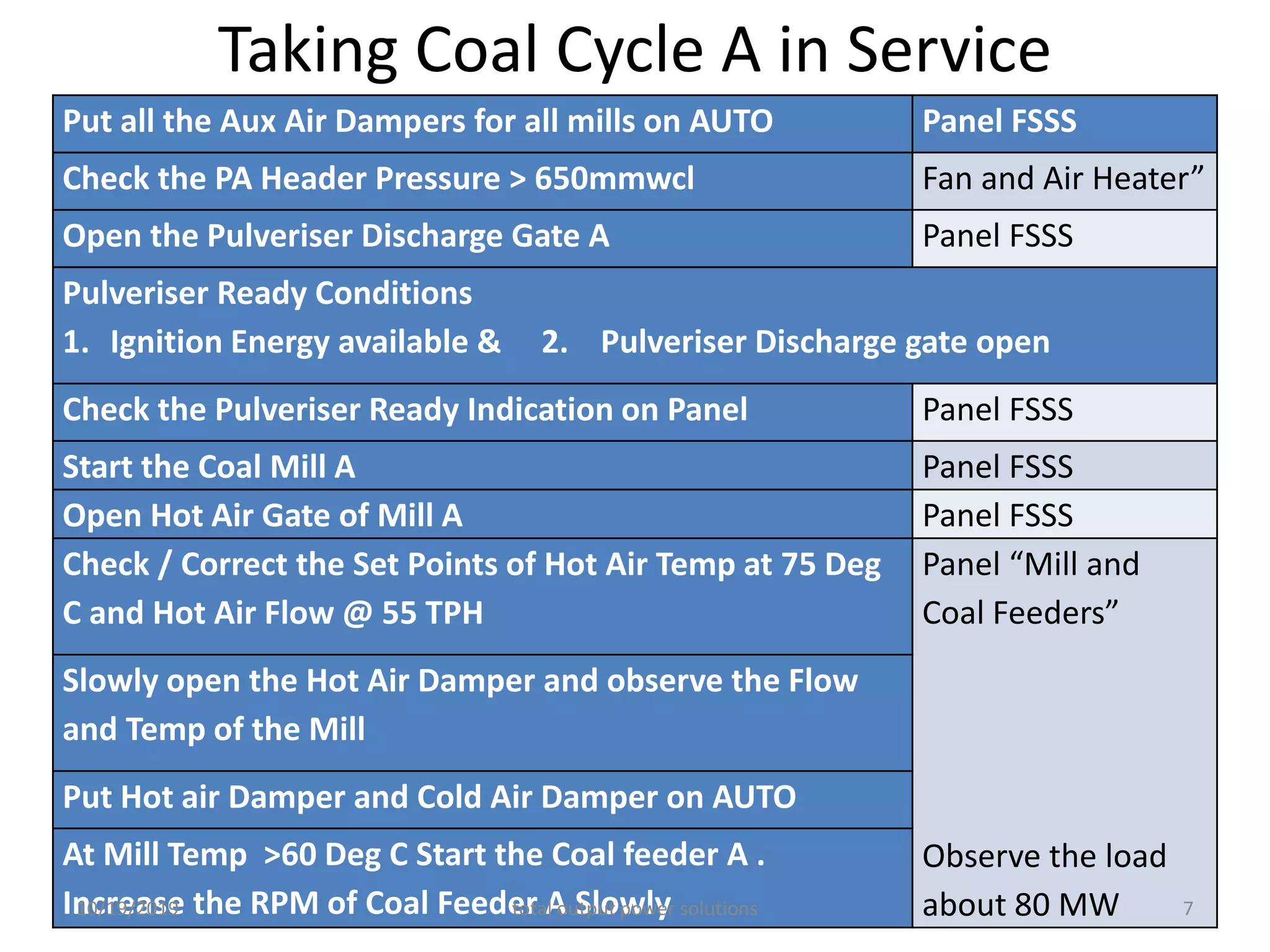

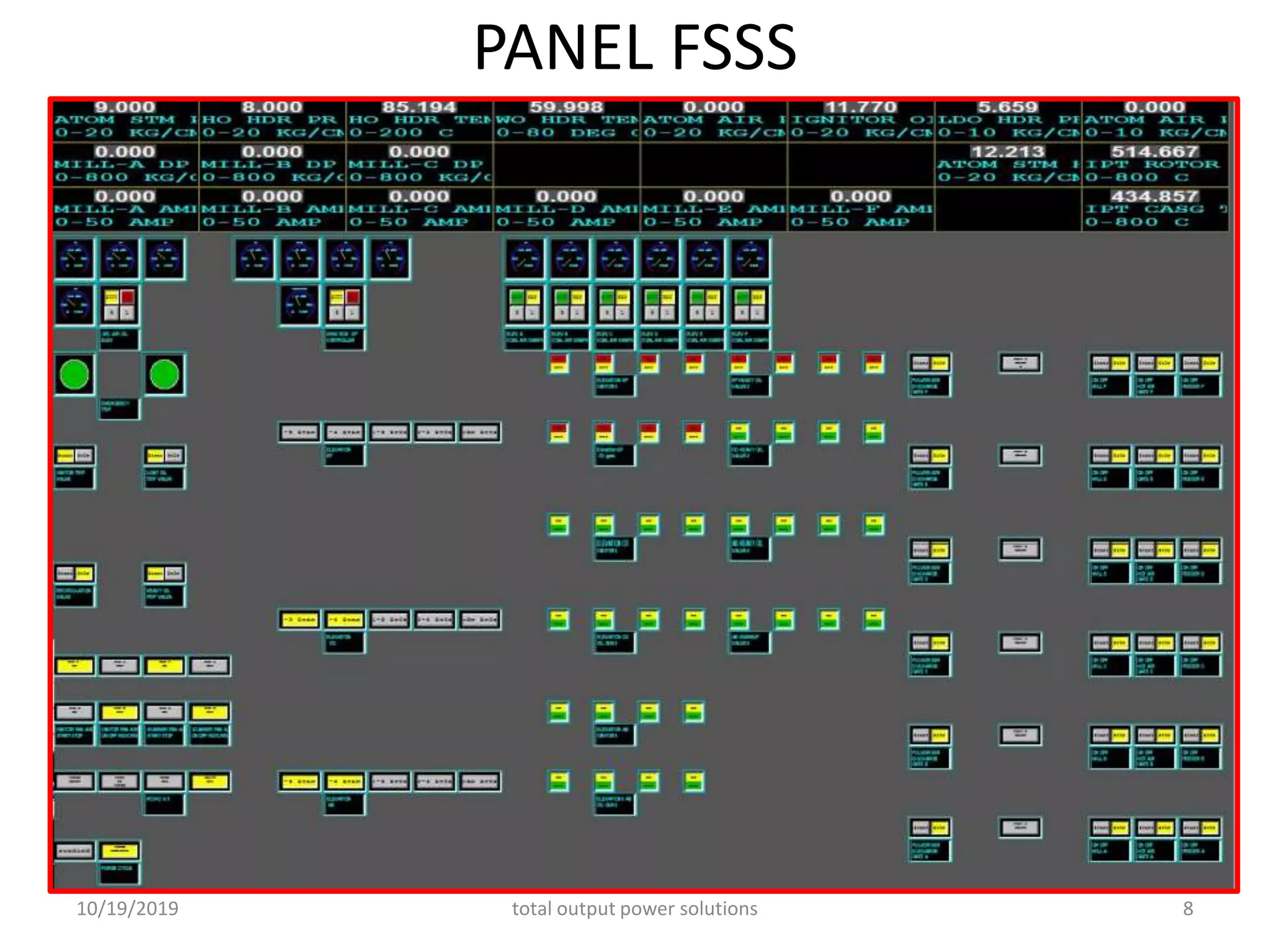

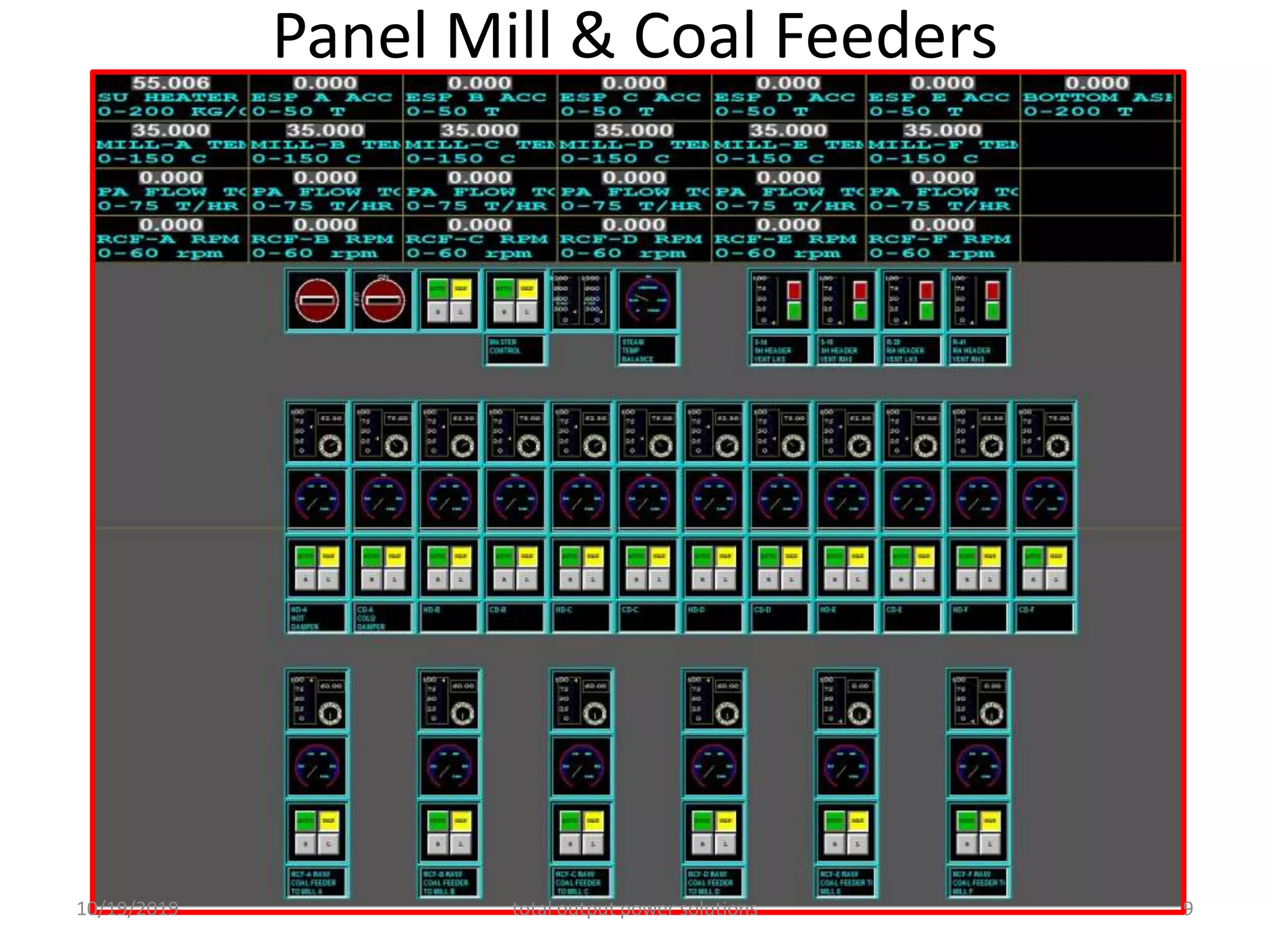

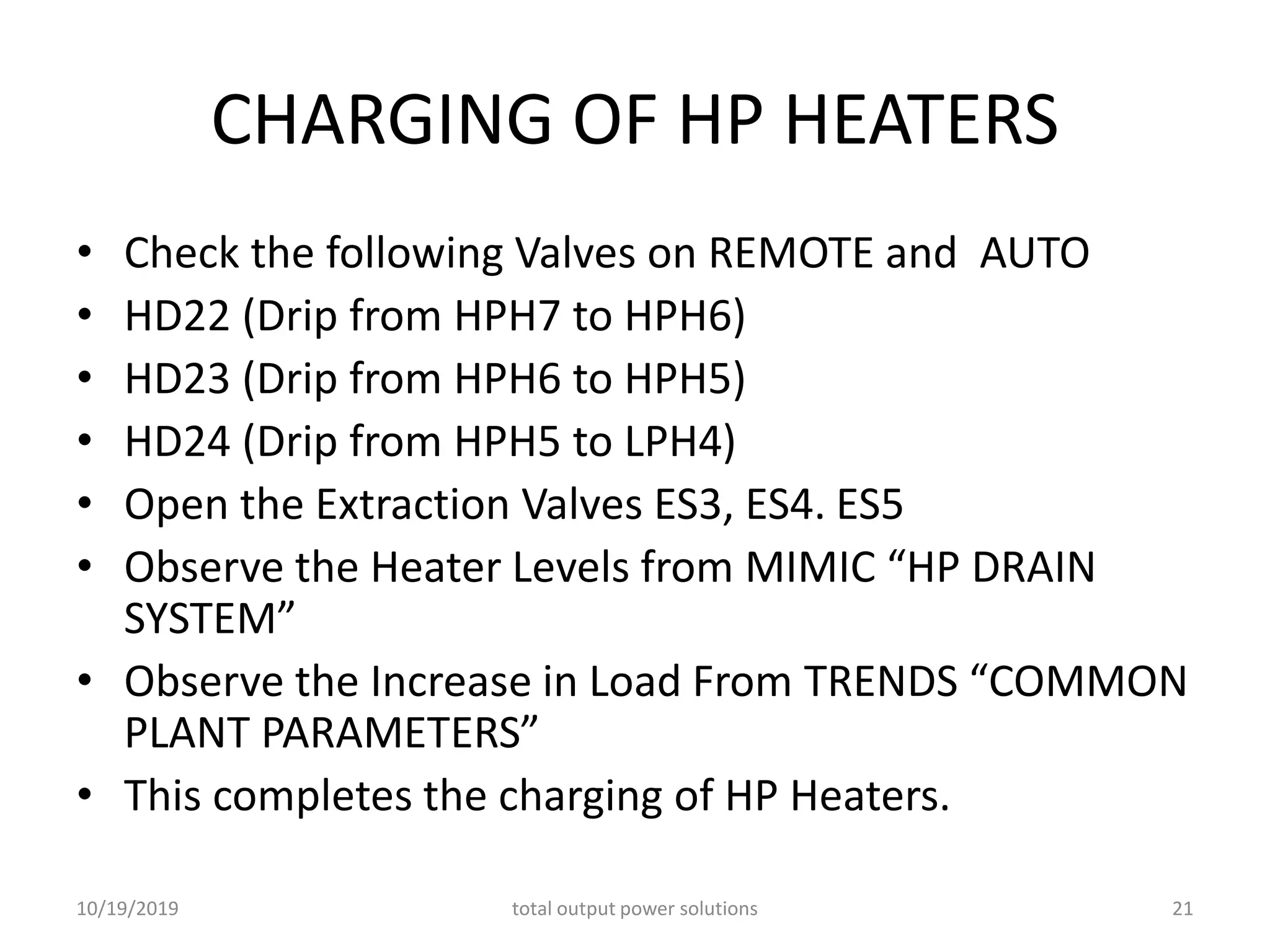

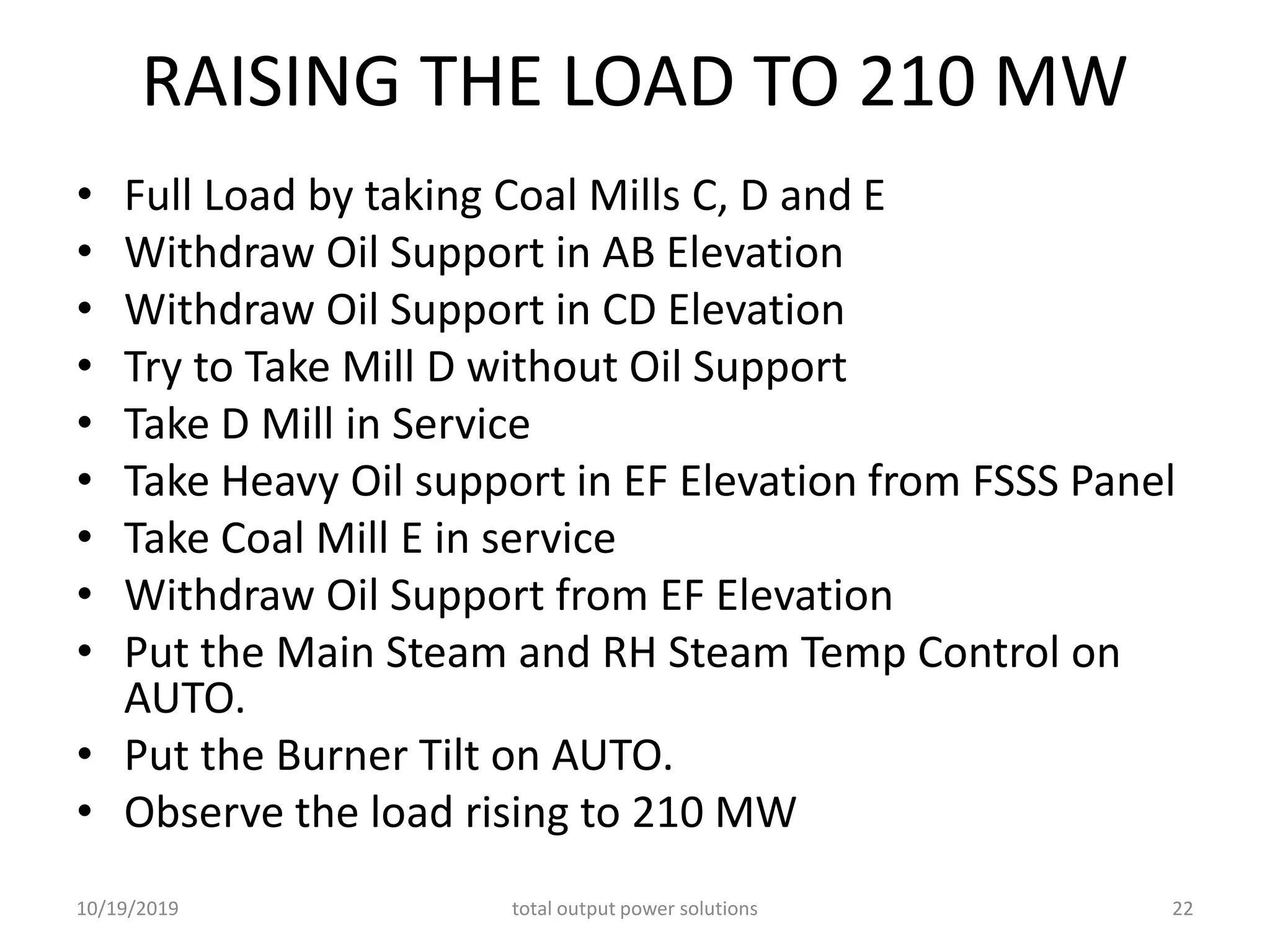

This document provides instructions for operating a thermal power plant over the course of a day. It includes starting various systems like the coal handling plant, primary air fans, mills and coal feeders to start producing power. It also details increasing the load by bringing additional mills online and adjusting support systems. The goal is to eventually reach full load of 210 MW by following the specified procedures.