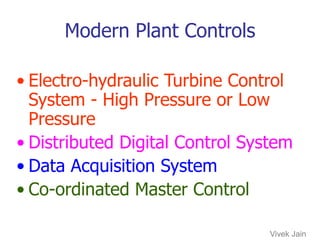

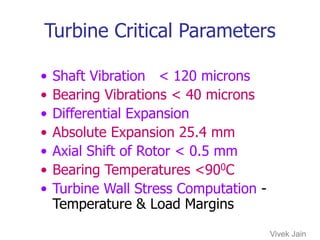

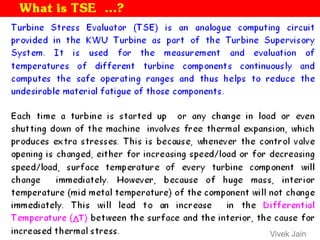

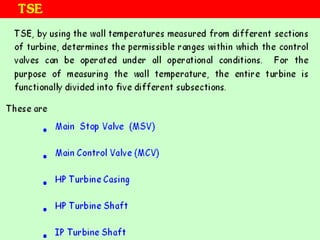

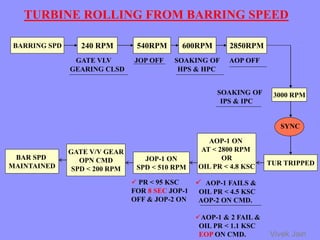

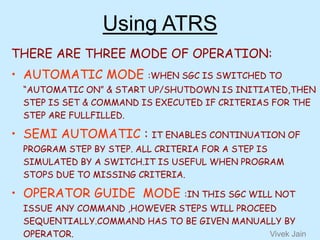

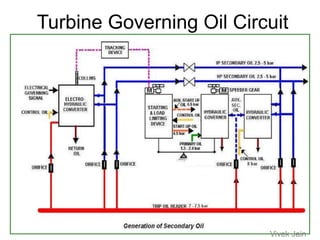

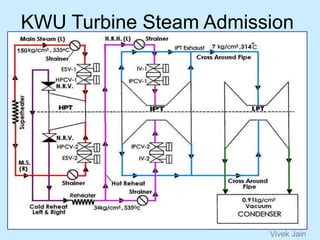

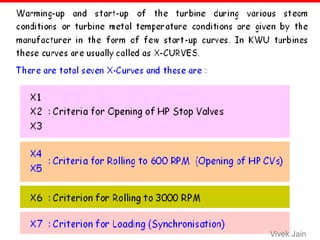

This document discusses turbine rolling and steam parameters. It describes modern turbine control systems like electro-hydraulic controls and distributed digital controls. It outlines critical turbine parameters that are monitored like shaft vibration, bearing vibration, expansion, and stresses. The document discusses two methods for rolling the turbine - manually or using an Automatic Turbine Run-up System (ATRS). It provides details on the different operating modes of ATRS and the steps for rolling the turbine from barring speed to synchronization using ATRS.