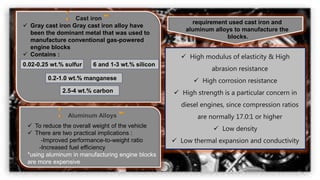

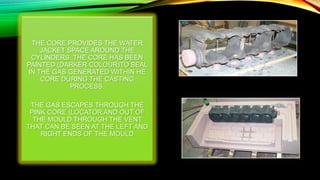

This document summarizes the manufacturing process of an engine block. It discusses the key requirements for engine blocks including high strength, corrosion resistance, and the ability to withstand stress and high temperatures. It then describes the typical materials used, which are gray cast iron and aluminum alloys. The document outlines the casting process for manufacturing engine blocks including creating molds, pouring molten metal, and machining the final product. Alternative die casting is also mentioned.