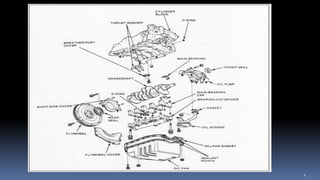

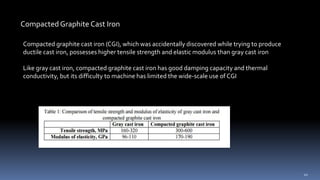

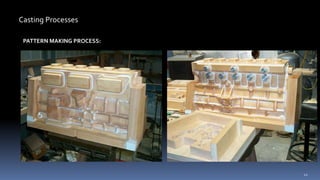

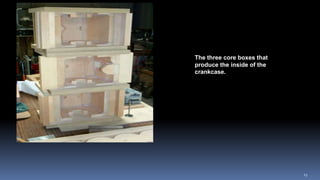

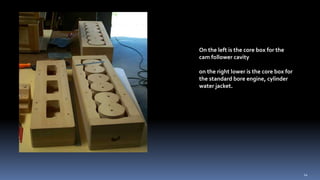

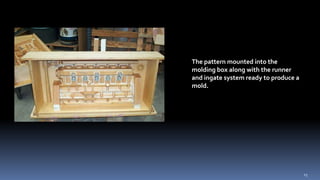

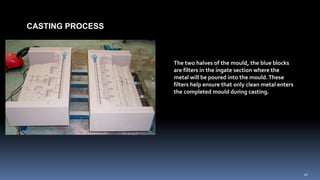

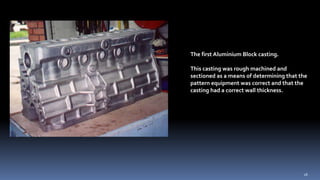

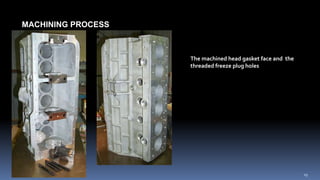

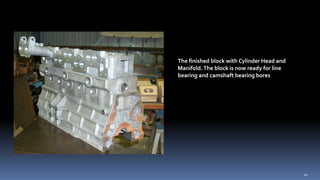

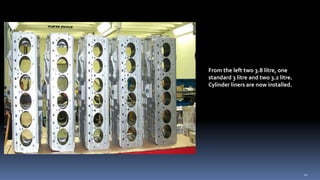

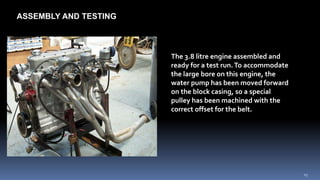

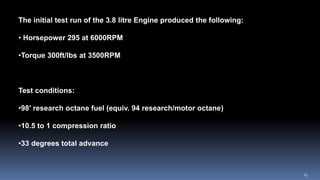

The document provides an overview of engine blocks, detailing their structural importance, functional requirements, and material properties necessary for performance. It discusses the advantages and disadvantages of materials like cast iron and aluminum alloys in manufacturing engine blocks, along with the casting and machining processes involved. The final sections illustrate the assembly and testing of a 3.8-litre engine with performance results.